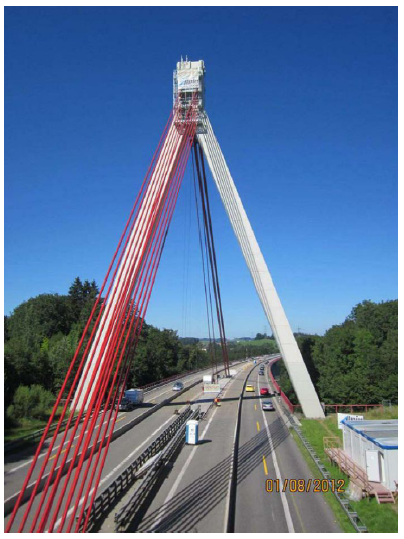

The Obere Argen viaduct is a 730 m long bridge structure on the Federal Motorway 96. The motorway overpass consists of a single-hip cable-stayed bridge in combination with a sub-tension. The bridge spans the Obere Argen and two farm roads with nine fields at a maximum height of 40 m. Because of a sliding slope, the southern end span has a span of 258 m. In the northern section, the two-part structure consists of a 381 m long prestressed concrete box girder bridge, which is separated from the southern part with a 349 m long steel bridge by double piers with an expansion joint in between. The prestressed concrete bridge has two separate superstructures, in the longitudinal direction with a continuous beam. In the transverse direction, the superstructures are designed as single-cell hollow boxes. The steel bridge has a common superstructure for both directional carriageways with a continuous beam in the longitudinal direction. In the transverse direction, the superstructure is designed as a single-cell hollow box with a 29 m wide orthotropic carriageway slab.

Object description

(No object description available.)

Civil engineering type

:

Year of construction

:

1990

Composed of materials

:

Location coordinates

:

47° 38' 25.86" N, 9° 44' 41.58" E

Country

:

Loading map...

{"minzoom":false,"maxzoom":false,"mappingservice":"leaflet","width":"auto","height":"350px","centre":false,"title":"","label":"","icon":"","lines":[],"polygons":[],"circles":[],"rectangles":[],"copycoords":false,"static":false,"zoom":false,"defzoom":6,"layers":["OpenStreetMap"],"image layers":[],"overlays":[],"resizable":false,"fullscreen":false,"scrollwheelzoom":true,"cluster":false,"clustermaxzoom":20,"clusterzoomonclick":true,"clustermaxradius":80,"clusterspiderfy":true,"geojson":"","clicktarget":"","imageLayers":[],"locations":[{"text":"\u003Cdiv class=\"mw-parser-output\"\u003E\u003Cp\u003ECable-stayed bridge Obere Argen\n\u003C/p\u003E\u003C/div\u003E","title":"Cable-stayed bridge Obere Argen\n","link":"","lat":47.64051666666667,"lon":9.744883333333334,"icon":"/images/imsafe/c/c8/Blue-marker.png"}],"imageoverlays":null}

Object analysis

A test matrix describes all tests to be carried out according to the time interval to be observed, needs tests or according to an object-related damage analysis. The inspection of the cable-stayed bridge includes an optical inspection of the ropes, an inspection of the rope entry and end anchoring, magnetic inductive measurements, an ultrasonic inspection of the end anchoring, rope force determination with frequency measurement, optical inspection of the superstructure inside and outside, a measurement of the reflectors on the superstructure and pylon, optical inspection of the Pylon and pylon head, measurement of the pillars, an inclinometer and deformation measurement of the site as well as a review of the seepage and drainage system.

Object state

The optical inspection of the ropes revealed damage to the coating, bulges, bubbles, rust spots and broken wires in the outer layer. No breaks could be found in the rope anchoring. Any bumps that are discovered are recorded and documented in a bump log. It is assumed that the occurrence of bulges was caused by larger deformations with cutting force redistribution in the center of the field, which were measured from 1990 onwards. From 2003 to 2007 no further changes could be measured. The seepage pipes at the abutment and the retaining foundation were driven over with a camera in 2005. This inspection showed that the pipes were sintered up to 70% or clogged by external influences and only a part of the pipes could be inspected by a camera inspection. In 2013 the drainage is to be made accessible with inspection shafts. Only then can a decision be made as to whether repairs can be carried out.

Observed deterioration processes

:

Observed damage types

:

Performance indicators

:

Deformation, Displacement, Material mechanical properties, Load bearing capacity, Spatial properties (concrete cover/duct voids), Cracks (width/length/pattern), Anomalies (delamination/spalling)

Images

Documents

This case study was contributed by Florian Fliegel of AEC3. Last edited by technical staff.