Magnetic and electrical methods

Goal(s)

Main objective

Electromagnetic methods have been widely used in detection of corrosion in post-tensioned concrete elements. In case of bridge infrastructure management, the most used techniques are based on the electromagnetic pulse induction technology. Structural performance of concrete is affected by the arrangement of the rebars and their dimensions. Those include especially on-site tests with simple or advanced covermeters. In the future their functioning mode can be extended with detailed tomography of the structure with more advanced software. Pulse induction technologies are exploited primarily for qualitative analysis, such as localization of the rebars in structure, determination of their dimensions and diameter of cover.

On the other hand, there is another group of quantitative magnetic methods basing on magnetic field fluctuations and inverse magnetostrictive effect (Villary effect). From the point of view of bridge maintenance, the significant ones are methods based on magnetic field variation due to prestressing such as Magnetic Memory Method (MMM) or Pulsed Eddy Current Method (PEC). Those are also known in energy industry for determination of the most critical areas and equipment having stress concentration. The magnetic flux leakage method can be also used in structural health monitoring. One of the promising technology in area of magnetic methods is the iCAMM – Infrastructure Corrosion Assessment Magnetic Method, which is currently under studies and development. Details can be found in -

There are quite a few modifications of magnetic methods such as:* Eddy Current Array Method (ECA),

- Alternating Current Field Measurements, but those have minimal use in diagnostics of bridges and mostly used for diagnostics of power machinery components.

Description

Functioning mode

- Electromagnetic Pulse Induction Methods – by means of covermeters – search head generates the magnetic field on the tested area. The disturbance caused by the presence of the metal produces local change in field strength which is detected by the meter. LED Screen shows directly the proximity and location of the bars .

- Magnetic Memory Method (MMM) – magnetic field is introduced in vicinity of prestressed or post tensioned steel and variations of the field due to loss of rebars cross-section from corrosion or fracture are monitored . Details on the phenomena of magnetization can be found in .

- Magnetic Flux Leakage Method (MFL) - powerful magnet used to magnetize the conductive material under test. If there are defects such as corrosion or material loss — the magnetic field colloquially speaking - “leaks”. Probes incorporate a magnetic detector placed between the poles of the magnet where it can detect the leakage field. During inspection, a magnetic circuit of sorts forms between the part and the probe. The magnetic field induced in the part saturates it until it can no longer hold any more flux. The flux overflows and leaks out of the pipe wall and strategically placed sensors can accurately measure the three-dimensional vector of the leakage field. Probe have three sensors to accurately measure spatial components of the signal .

- Pulsed Eddy Current Response (PEC) - application of step voltage to a conductor, magnetic field develops around it. This field changes in intensity as the current alternates. If brought close to the first field, another conductor will have a current induced in it. If there are any flaws in the material then the eddy current will distort. The first conductor is an eddy current probe and the second is the test material. Secondary field is then detected by a sensing device, which typically can be either a magnetic sensor or a coil. The output signal of the sensing device is then passed to the next stage to be conditioned and processed where eventually features are extracted. Sensing devices can broadly be categorised into two different types, namely induction coils and magnetic sensors..

Types

- Electromagnetic Pulse Induction Methods – applied in covermeter and advanced covermeters (e.g. Profometers) with directional heads; search heads can be aligned parallel or perpendicular to the bar axis.

- Magnetic Memory Method (MMM) – applied in different monitoring instruments such as electromagnetic crack indicator, magnetometric stress concentration meter.

- Magnetic Flux Leakage Method (MFL) – computerized system such as scanner is a designed to detect, size and map under corrosion; applied influx meter.

- Pulsed Eddy Current Response (PEC) – applied in an assembled system with various equipment, components, and accessories including coil, direct current power supply, oscilloscope, function generator, amplifier.

Process/event to be detected or monitored

- Electromagnetic Pulse Induction Methods – maximum response on the surface of concrete during scanning with search head of covermeter.

- Magnetic Memory Method (MMM) – variations of the magnetic field due to loss of section from corrosion or fracture are monitored. Change of the magnetic susceptibility of a material when subjected to a mechanical stress, dependence of the magnetic field strength on the distance of the probe from the beginning of the measurement.

- Magnetic Flux Leakage Method (MFL) - variations of the magnetic field – sensors measure variations of the field due to the presence of flaws.

- Pulsed Eddy Current Response (PEC) – transient voltage response in time (s), the relationship between the diameter of rebar and long-time decay slope.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical and chemical properties, relative displacements of the two sides of a crack, etc.).

- Electromagnetic Pulse Induction Methods – the diameter of cover [mm]; diameter of rebar [mm].

- Magnetic Memory Method (MMM) – the change of the magnetic susceptibility of a material when subjected to mechanical stress, magnetic permeability is measured [μ].

- Magnetic Flux Leakage Method (MFL) – the change of voltage in the measuring coils.

- Pulsed Eddy Current Response (PEC) - determination of reduced diameter of rebar due to corrosion process when compared to original diameter, independent of rebar depth into concrete structure.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

Measurement range

- Electromagnetic Pulse Induction methods:

-

- nominal diameter of the rebars: 13 mm and less up to 38 mm,

- distance between rebars: within 75 mm,

- distance on the structure: 3 m or more,

- cover range: depends on the manufacturer of covermeter used- from 5 to 185 mm.

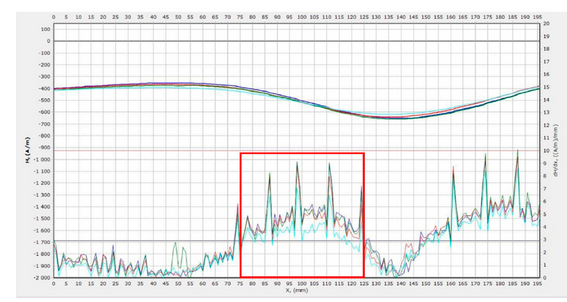

- Metal Magnetic Memory Method:

-

- range of the magnetic field measured: - 2000 T to + 2000 T.

- Magnetic Flux Leakage Method:

-

- range for the material thicknesses up to 10 mm – losses up to 20% detected,

- range for the material thicknesses up to 13 mm – losses up to 40% detected.

- Pulsed Eddy Current Response (PEC):

- range of the magnetic field measured: 10−15 T up to around 100 mT.

Measurement accuracy

- Electromagnetic Pulse Induction Methods:

- location: within ±10 mm or ± 1.0% of distance between centres of rebars,

- cover depth: within 5+ actual value of cover depth × 0.1 in mm,

- rebar diameter: ±2.5 mm.

- Metal Magnetic Memory Method:

- depends on the systems configuration, calibration and type of sensors used.

- Magnetic Flux Leakage Method: depends on the systems configuration, calibration, and type of sensors used.

- Pulsed Eddy Current Response (PEC):

- depends on the systems configuration, calibration, and type of sensors used.

- sensitivity to defects depends on eddy current density at defect location

- able to detect surface cracks greater than 2.0 mm in length.

Background (evolution through the years)

The principles of eddy current testing were first laid out in 1831. Later on, there was the discovery that the properties of a coil would change when placed in contact with metals of different connectivity and permeability. The concept of Metal Magnetic Memory was first introduced in 1994 in archeological studies. ММM method has been developed in practical and theoretical aspects for 20 years. Until 2004 there are more than thirty guiding documents on the method .

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

Procedures for defining layout of the survey

Sensibility of measurements to environmental conditions.

Preparation

Procedures for calibration, initialisation, and post-installation verification

- Electromagnetic Pulse Induction methods:

- accuracy is affected by the concrete composition. The same concrete sample that will be tested should be used to avoid influence of iron content in the cement and aggregate in composition. For covermeters calibration should be carried out regularly, with a sample of concrete at predefined distances of the rebars from the surface.

- MFL method:

- for calibration there are used plates with diameter o 6 – 12 mm from the same material as tests sample.

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Criteria for the successive surveying campaigns for updating the sensors. The campaigns include: (i) Georeferenced frame, i.e. the global location on the bridge; (ii) Alignment of sensor data, relative alignment of the data collected in a surveying; (iii) Multi-temporal registration to previous campaigns; and (iv) Diagnostics.

Reporting

The report from the survey should include: date, type of concrete used, place of test, environmental conditions, location of the tested areas, type of covermeter or other equipment used and last calibration performed, results, interpretation of results, conclusions.

Lifespan of the technology (if applied for continuous monitoring)

- Electromagnetic Pulse Induction Methods: Covermeters are not used continuous monitoring.

- Magnetic Memory Method (MMM)

- Magnetic Flux Leakage Method (MFL)

- Pulsed Eddy Current Response (PEC)

The technologies above can be used in real-time measurements that can be prolonged to a few hours. However, are not used in continuous monitoring for a longer period.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

- Electromagnetic Pulse Induction Methods - graphical distribution overview of the cover measurements on the digital display. Advanced covermeters: area scan with colors depicting the cover data in mm; the distance to and between reinforcing bars in mm;

- Magnetic Memory Method (MMM) – graphical data (direct or as gradient) in a form of so-called magnetograms.

- Magnetic Flux Leakage Method (MFL) - graphical data (direct or as gradient) in a form of so-called magnetograms.

- Pulsed Eddy Current Response (PEC) – graphical data of thickness correlated with the amount of time of decay of eddy currents.

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

- Electromagnetic Pulse Induction Methods – dimensions of the rebars, location in the structure, and cover depth.

- Magnetic Memory Method (MMM) – based on evaluation of magnetograms - determination of the zones with increased stress concentration, where is an increased probability of defects in the material structure; the size of the defects is related to the amplitude and shape of the magnetic signals.

- Magnetic Flux Leakage Method (MFL) - corrosion maps of inspected areas; localization of defects and their parameters.

- Pulsed Eddy Current Response (PEC) - corrosion maps of inspected areas created automatically In the software; localization of defects and their parameters. The eddy current method relies on evaluating received eddy current signals containing information about the material characteristics. It is necessary to use applicable reference samples to properly inspect and analyze signals of interest. The reference samples used, therefore, must be made of similar materials with similar electrical and mechanical properties as those materials to be examined. This interpretation of eddy current signals to ascertain the integrity of the test parts, thus, depends largely on the selection and choice of suitable reference samples.

Validation

Specific methods used for validation of results depending on the technique

Quantification of the error

Quantitative or qualitative evaluation

Detection accuracy

- Electromagnetic Pulse Induction Methods:

- Magnetic Memory Method (MMM):

- Magnetic Flux Leakage Method (MFL) -

- Pulsed Eddy Current Response (PEC):

Advantages

- Electromagnetic Pulse Induction Methods:

- fast and easy to operate

- simple read-out of the results

- not affected by environmental influences

- Magnetic Memory Method (MMM):

- low-cost magnetoresistive sensors used

- allows real-time monitoring

- good sensitivity in wide range of magnetic field fluctuations

- detection of early damages

- Magnetic Flux Leakage Method (MFL):

- very powerful in scanning a large areas

- efficient and easy operation

- Pulsed Eddy Current Response (PEC):

- can be done without need for contact with the surface of the material

- useful in situations where an object’s surface is rough or inaccessible

- does not require surface preparation or removing any insulation. It can be a quick and cost-effective solution for corrosion detection

- possibility of location of the reinforcement and dimensions of the rebars with high accuracy

- quality control of the cover of reinforcing bars after concrete placement

- possibility of studying the elements for which no records or historical data are available

- good sensitivity to pitting

- high-speed inspection.

Disadvantages

- Electromagnetic Pulse Induction methods:

- dependency on cover depths for minimum bar spacing detection

- restricted detection range

- Magnetic Memory Method (MMM):

- signals are prone to be easily interfered

- low repeatability and reliability

- Magnetic Flux Leakage Method (MFL):

- *very poor for detecting axial cracks

- dimensions of the defects are limited

- Pulsed Eddy Current Response (PEC):

- impossible detection of small pitting

edge effect near metallic surfacesPossibility of automatising the measurements

Advances of magnetic methods are mainly in development of novel systems, for future purposes of structural health monitoring in concrete .

The Pulsed Eddy Current instrument can be operated by remote control, e.g. for use in Remote Operated Vehicles (ROV’s).

Barriers

Particular issues can be pointed out for Electromagnetic Pulse Induction methods:* if other reinforcing bars, metal tie wires, bar supports are present in the area of tests the results will be affected

- if there is extensive corrosion and migration of the products, misleading results can be obtained

- if the reinforcing bars are closely packed the method is not suitable

- if rough surfaces are present the accuracy is reduced in significant way

- for rebars below 10 mm diameter the results are not reliable

It should be noted that MFL equipment is generally not intrinsically safe and should not be operated in a potentially explosive environment. MFL equipment generates strong magnetic fields and can present some hazards to the operators and electronic equipment. There can be a significant difference in the performance of individuals carrying out any MFL inspection. Thus it is important that their approach to MFL inspections follow the guidelines of the Recommended Practice document to ensure that the thoroughness, coverage and capability of the inspection are maximised.

Existing standards

- BS 1881: Testing concrete: Part 204 Recommendations on the use of electromagnetic covermeters: 1988, Dec. 1989.

- BS 1881 Part 5:1970: Testing Concrete. Methods of testing hardened concrete for other than strength. Determination of dynamic modulus of elasticity by electromagnetic method.

- BS 4408: pt. 1, Non-destructive methods of test for concrete-electromagnetic cover measuring devices”, British Standards Institution, London.

- DIN 1045: Guideline Concrete, reinforced and prestressed concrete structures.

- GOST R 52081-2003: Nondestructive testing. Method of metal magnetic memory. The terms an definitions.

- GOST R 52005-2003: Nondestructive testing. Method of metal magnetic memory. General requirements.

- ST RWS 004-03: Nondestructive testing. Welded joints of equipment and constructions. Method of metal magnetic memory.

- ISO 24497-1:2020 Non-destructive testing — Metal magnetic memory — Part 1: Vocabulary and general requirements.

Applicability

Relevant knowledge fields

- Civil engineering:

- pipelines,

- bridges,

- bricks,

- vessels,

- piping systems,

- storage tanks.

- Aerospace sector:

- aircraft and spacecraft inspection,

- jet engines and turbines.

- Railroad Industry:

- integrity of railroad infrastructure.

- Offshore facilities:

- oil and gas platforms inspection.

- Heat exchangers

Performance Indicators

- cracks,

- corrosion of the reinforcement bars,

- loss of section,

- reinforcement bar failure/bending,

- bending,

- delamination

Type of structure

- bridges,

- tunnels.

Spatial scales addressed (whole structure vs specific asset elements)

Investigation with covermeters is performed mostly for structures that are available only from one side and in depicted areas. Other methods are suitable for rebar junctions, griders. For assumptions on the whole structure additional non-destructive or destructive methods should be performed. * water pipes,

- lighting conduits

- girders

- columns

- bridge slabs

- reinforced walls

- concrete slab soffits

- retaining walls

- welded joints

Materials

- concrete,

- reinforced concrete,

- steel,

- silicate,

- ferromagnetic materials,

- polymer coatings.

Available knowledge

Reference projects

TRANSPORT2020+, PROJECT No. CK01000108: New approaches in the diagnosis of reinforcement of pre-stressed/ post-tensioned concrete bridge beam (Technological Agency of the Czech Republic).

Other

The covermeters are being under study in order to upgrade the equipment to perform tomography of rebars with 2D scanning. The recent advances in MFL technology are in automatic detection and sizing defects .

One of the promising concepts in the area of magnetic methods is the iCAMM – Infrastructure Corrosion Assessment Magnetic Method, which is currently developed. Details can be found in - .

Manufacturers:

ENERGODIAGNOSTYKA – Diagnostics with use of Metal Magnetic Memory Method

ZETEC – Eddy Current testing of Galvanized Steel: Best Practices.

ZETEC – Advanced Eddy Current Instruments for Eddy Current

Eddyfi Technologies – Magnetic Flux Leakage equipment and software/ Pulsed Eddy Current equipment/ Eddy Current Array equipment.

Rosen Group – Magnetic Flux Leakage solutions

Intertek – Non-destructive inspections with Magnetic Flux Leakage

Bibliography

- BS 1881 Part 5:1970: Testing Concrete. Methods of testing hardened concrete for other than strength. Determination of dynamic modulus of elasticity by electromagnetic method. (1970).

- A. Raine, M. L. (1999, September 1). A review of the alternating current field measurement inspection technique. Engineering.

- Bhagi, P. C. (2012). Magnetic Flux Leakage Technique: Basics. Nondestructive Testing and Evaluation, pp. 7-17.

- British Standards Institution. (1988). Testing concrete. Part 204, Recommendations on the use of electromagnetic covermeters. London: British Standards Institution.

- BS 1881: Testing concrete: Part 204 Recommendations on the use of electromagnetic covermeters. . (1989, 12).

- Craik D.J., W. M. (1970). Magnetization changes induced by stress in a constant applied field. Phys. D Appl. Phys. vol 3 no 7, pp. 1009-1016.

- D. C. Hurley, K. H. (1992, January). Eddy Current Arrays for Defect Detection. Review of Progress in Quantitative Nondestructive Evaluation, pp. 1137-1144.

- D.C., J. (1955). Theory of the magnetomechanical effect. . Phys. D Appl. Phys. vol 28 no 8, pp. 1537-1546.

- Dai X W, L. R.-c.–3. (1990). Numerical simulation of pulsed eddy-current nondestructive testing phenomena. IEEE Transactions on Magnetics, 1990: 26(6): 3089–3096. IEEE Transactions on Magnetics 26(6), pp. 3089-3096.

- Drobiec, Ł., Jasinski, R., & Mazur, W. (2019). Accuracy of Eddy-Current and Radar Methods Used in Reinforcement Detection. Materials 2019, 12, 1168. Materials 1168.

- Dubov, A. A. (2012). Development of a metal magnetic memory method. Chemical and Petroleum Engineering Vol. 47, pp. 837-839.

- García-Martín, J., Gómez-Gil, J., & Vázquez-Sánchez, E. (2011). Non-Destructive Techniques Based on Eddy Current Testing. Sensors, pp. 2525–2565.

- Géraldine Villain, R. D. (2015). Use of electromagnetic non-destructive techniques for monitoring water and chloride ingress into concrete. Near Surface Geophysics 13(2068).

- Ghorbanpoor, A. B. (2000). Magnetic-Based NDE of Prestressed and Post-Tensioned Concrete Members: The MFL System. Washington,: Federal Highway Administration,.

- Herman, S. L., & Duff, J. R. (2011). Alternating current fundamentals. New York: Delmar Cengage Learning.

- Hüblová, S. &. (2019). Experimental measurement of the diameter and cover depth of steel reinforcement using an electromagnetic concrete cover meter. IOP Conference Series: Materials Science and Engineering 5.

- Ian Eddy, P. R. (2020). Pulsed Eddy Current Response to General Corrosion in Concrete Rebar. Journal of Nondestructive Evaluation, Diagnostics and Prognostics of Engineering Systems, vol 3 no 4, pp. 1-20. Retrieved from https://www.researchgate.net/publication/343118758_Pulsed_Eddy_Current_Response_to_General_Corrosion_in_Concrete_Rebar

- International Atomic Energy Agency. (2002). Guidebook on non-destructive testing of concrete structures. Training Course No.17. Vienna: IAEA.

- Karel Pospisil, M. M. (2021, 03). Diagnostics of Reinforcement Conditions in Concrete Structures by GPR, Impact-Echo Method and Metal Magnetic Memory Method. Remote Sensing vol 13 no 5. Retrieved from https://www.researchgate.net/publication/349805789_Diagnostics_of_Reinforcement_Conditions_in_Concrete_Structures_by_GPR_Impact-Echo_Method_and_Metal_Magnetic_Memory_Method

- Lebrun B, J. Y.-C. (1997). Pulsed eddy current signal analysis: application to the experimental detection and characterization of deep flaws in highly conductive materials. NDT E Int. 30(3), pp. 163-170.

- M. Mosharafi, S. M. (2018). Simulation of real defect geometry and its detecion using passive magnetic inspection (PMI) method . Applied Science 8(7), 1147.

- M. Mosharfari, S. M. (2020). Magnetic detection of corroded still rebar: Reality and simulations. NDT &E International 110 .

- Maierhofer, C. (2010). Non-destructive evaluation of reinforced concrete structures. Volume 2: Non-destructive testing methods. Cambridghe: Woodhead Publishing Ltd. .

- Pelkner, M., Pohl, R., Erthner, T., Stegemann, R., & Kreutzbruc, M. (2015). Eddy current testing with high-spatial resolution probes using MR arrays as receiver. In: 7th International symposium on NDT in aerospace, Germany. Bremen.

- S.B. Mahbaz, M. D. (2017). Detecting defects in steel reinforcement using the passive magnetic inspection method. . J Environ Eng Geophys 22 (2) , pp. 153-166.

- Simon X Yang, R. Z. (2018, 11). A STRESS DETECTION METHOD FOR REINFORCED CONCRETE STRUCTURE BASED ON METAL MAGNETIC MEMORY. International Journal of Robotics and Automation, vol. 33 no 6. Retrieved from https://www.researchgate.net/publication/328919583_A_stress_detection_method_for_reinforced_concrete_structure_based_on_metal_magnetic_memory

- Singapore Institute of Standards and Industrial Research. (1992). Testing concrete. Part B4, Recommendations on the use of electromagnetic covermeters. Singapore : Singapore Institute of Standards and Industrial Research.

- Vlasov V., D. A. (2004). Physical bases of the metal magnetic memory method. . Moscow: ZAO Tisso.

- Yanhua Sun, S. L. (2017, January 3). Magnetic flux leakage structural health monitoring of concrete rebar using an open electromagnetic excitation technique. Structural Health Monitoring 17(2), pp. 121-134.