Mechanical tests on cored samples

Goal(s)

Main objective

Quality control of produced concrete usually consists of few stages, such as production quality tests on fresh concrete, quality tests on hardened concrete, and tests performed on final structures. In the last case, which is important from the point of view of maintenance of bridges or tunnels, mechanical destructive test should be performed as a part of inspection in life cycle of the object. Mechanical tests performed on hardened concrete are a part of destructive surveying techniques used for characterization of concrete properties, such as compressive strength, that will affect the durability of the different structural elements of bridges or tunnels. In practical applications, it is necessary to combine different survey technologies in order to receive a more accurate and global view of the structural condition. Mechanical tests performed before construction in new bridge facilities will prevent potential failures in the future. In the case of existing ones, used as a complementary set of tests to other non-destructive or semi-destructive techniques .

The methods described below are used in laboratory conditions play a very important role in a reliable assessment of the safety of constructions such as bridges or tunnels. The selection of the test methodology should take into account both the properties of the concrete itself, as well as the mechanism of its wear in the structure. Test methods should reflect the environmental and structural damaging effects as closely as possible.

Description

Functioning mode

The first step before the actual measurement in the laboratory involves samples collecting and preparation for all mechanical tests. Concrete samples are taken directly from structural elements of the object such as a bridge or tunnel in the form of drill cuttings from three different depths. The depth of the last borehole should correspond to the cover thickness of the bars armaments. Drilling locations are selected based on the visual assessment of the object. The most damaged or most exposed places should be considered first. Samples are also taken from places without visible damage as control tests. Drill cuttings are dried and sealed in the described containers and transported to the laboratory .

Having this stage completed and documented following mechanical tests can be performed:

1.3.1.1 Compressive strength test – samples of concrete are subjected to increasing load in a compression testing machine and the maximum load in which the sample failure occurs is detected

1.3.1.2 Fatigue test – cured samples of concrete are placed in fatigue testing machine and subjected to pre-defined load and then unloaded to zero loads or loads in opposite direction; cycles are repeated until the end of the test; in general, there are many types of measurement, such as:

- torsional fatigue testing,

- rotating fatigue testing,

- plane bending fatigue testing,

- fatigue crack propagation testing,

- simulated environment fatigue testing,

as a result of the fact that there are different types of fatigue such as mechanical, creep, thermal, fretting, or corrosion .

1.3.1.3 Torque test - torque testing is a way of determining how an object will react when it is being turned - during normal operation or being twisted until it deliberately fails or breaks. Test is performed for steel anchors, which are used for fastenings in building materials .

1.3.2.4 Tensile tests:

- Split Cylinder test – concrete cylindrical sample is placed horizontally in the testing machine and subjected to loading along the diameter, which results in lateral tensile stress and causes a splitting along with the sample,

- Uniaxial tensile test – concrete sample is held by ends in the testing machine and disrupted, which cause uniaxial tensile stress,

- Flexure test – in this case, the concrete beam is subjected to loading in four points until rupture occurs, because of tensile stresses induced in the material and after the modulus of rupture can be defined .

1.3.2.5 Abrasion resistance test – generally there are four modes of measuring the abrasion resistance for concrete, from which rotating-cutter method is designed for drilled concrete samples:

- sand blasting – in this method abrasion is generated by sandblasting and based on the simulation of movement of the particles on the road surface in traffic,

- underwater method – designed for hydraulic structures – in this method abrasive charges on the surface of the concrete sample are moved by water circulating with high speed which leads to abrasive effects,

- rotating-cutter machine test for drilled samples,

- abrasion resistance test of horizontal concrete surfaces'.

Types

1.3.2.1 Compression test:

- standard testing machine adjustable for the type of sample examined, which can be powered hydraulically or electromagnetically.

1.3.2.2 Fatigue tests:

- performed with hydraulic test machines, consisting of a frame for the sample placement, load cell, grips, and testing software.

1.3.2.3 Torque test:

- Torque Penetrometric test for in-situ purposes with a dynamometric torque wrench with display (0-30 Nm range and 0,5 Nm precision); with digital or analogic transducer; provided with a recording device to store the parameters measured during the test.

- precision torque testers controlled by software.

1.3.2.4 Tensile tests:

- machine consisting of steel frame, columns, and self-centering sample holder; load beam suspended with springs for adjustment to the sample.

1.3.2.5 Abrasion resistance test:

- rotating-cutter machine - testing machine consists of abrading cutter and drill press with lever, gear, spring system e abrading cutter when using the lever, gear and spring system of a drill press.

Process/event to be detected or monitored

- Compression test – a moment of failure of the sample under applied compressive load;

- Fatigue test – fatigue cracks resulting from cyclic stresses applied to the sample; observation if a minimum number of cycles of fatigue loads there will be any partial or complete damage, such as visible transverse crack;

- Torque test –failure of the anchor if either the bolt or the grout shows any movement;

- Tensile test:

- Split Cylinder test - splitting along diameter depending on the type of tensile test performed,

- Uniaxial tensile test – breakage of the sample in the middle,

- Flexure test – the crack of the sample due to force applied.

- Abrasion resistance test:

- determination of resistance to degradation of concrete when subjected to combine the action of impact and abrasion.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical and chemical properties, relative displacements of the two sides of a crack, etc.).

- Compression test – maximum load [N] at which failure of the sample has been registered.

- Fatigue test – force [N] needed to break the sample over a number of cycles of stress.

- Torque test – measurement of the maximum torque/rotational force resisted by the material; tension force in the bolt or screw as a function of the applied torque moment.

- Tensile test – force [N] needed to break the sample under load.

- Abrasion resistance test - average loss in mass [g] or depth of wear [mm].

Induced damage to the structure during the measurement

In all mechanical tests, there is damage induced to the structure since sample collection requires drilling into the structures.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

Measurement range

Measurement accuracy

Background (evolution through the years)

Already in the 20th century, there was a need to monitor concrete workability to ensure the quality control of the concrete mixes and achieve expected strength and hardness. Since then a lot of test procedures have been developed for mix proportioning, research and field use.

The majority of those did not find widespread acceptance, even though has been extensively developed. The main method used, even with increasing knowledge in concrete rheology, was the slump test. Modern concrete production has not limited only to monitoring concrete workability in the field. In 1998 National Ready Mixed Concrete Association identified the need for the characterization of high-performance concrete. However, even after 80 years of development, the industry is still facing problems with accurate, quick, and reliable mechanical testing methods .

In 2000 there was published norm EN 12504-1:2000, describing the methods of collecting the boreholes, their quality assessment, and measurement of the compression strength. In 2008 has been introduced the norm EN 1379:2008, which was directed at old, destroyed constructions for modernization, redesign .

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

- for compression tests:

- cubic samples 100, 150, 200, 300 mm,

- cylindrical samples 100 x 200 mm or 150 x 300 mm.

- for bending strength tests:

- cement bars 40 x 40 x 160 mm,

- concrete beams 100 x 100 x 500 mm or 150 x 150 x 700 mm.

- cubic samples 100 × 100 × 100 mm on the base of ASTM C 944 .

Procedures for defining layout of the survey

- visual inspection of the structure,

- decision regarding the places of drilling,

- identification of the samples,

- preparation of the samples for further testing in the laboratory,

- calibration processes for selected test,

- performance of the measurement,

- documentation of the results and observations,

- validation of results,

- conclusions and preventive actions.

Sensibility of measurements to environmental conditions

Preparation

Procedures for calibration, initialisation, and post-installation verification

- setting the test parameters - sample selection, rate of force increase) - the change is required only when the type of the tested sample changes,

- pressing start button on the control panel,

- wait for automatic control rate of force increase after reaching 1% of the range.

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Criteria for the successive surveying campaigns for updating the sensors. The campaigns include: (i) Georeferenced frame, i.e. the global location on the bridge; (ii) Alignment of sensor data, relative alignment of the data collected in a surveying; (iii) Multi-temporal registration to previous campaigns; and (iv) Diagnostics.

Reporting

Report from mechanical testing should include:

- date of the test,

- age of the concrete,

- composition of the concrete,

- conditions of curing and storage of the samples,

- identification of the samples, dimensions,

- measured quantities e.g. maximum load registered during compression test,

- observations e.g.

For abrasion test report should include also:

- sample dimensions,

- age of concrete,

- type of finish,

- concrete strength,

- applied surface treatment,

- time of abrasion and load used,

- average loss in grams.

Lifespan of the technology (if applied for continuous monitoring)

Mechanical tests can be repeated in different intervals of time, however, it is not possible to perform continuous monitoring.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

- Compression test – value of concrete strength calculated by dividing the maximum load [N] at failure by cross sectional area [mm2].

- Fatigue test - total number of load cycles to failure.

- Torque test – indication of load applied [N], maximum torque [N/m], maximum angle of twist.

- Tensile test – value of load [N] that caused sample failure; values can be exported to excel or on email address, depending on the software used.

- Abrasion resistance test – sample weight after the test [g], mass loss [g/%], average abrasion resistance and relative abrasion resistance value.

Software available on the market enables to present measurement data graphically and prepare customised test reports.

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

- Compression test – characteristic compressive strength is designated as a strength that will exceed 95% of the tested samples; characteristic strength for cubic sample, characteristic strength for cylindrical sample in [N/mm2] is calculated.

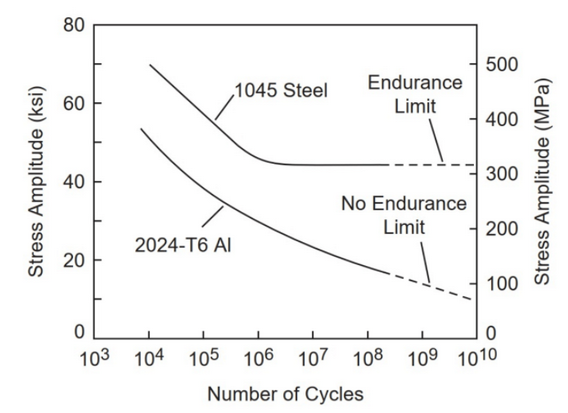

- Fatigue test – fatigue limit is a stress level below which there would be no fatigue failure disregarding the number of load cycles the material is subjected to; plot an S-N diagram from which fatigue strength can be determined. Example is shown below:

- Torque test – torsional strength and stiffness of the measuring element.

- Tensile test – mean tensile splitting strength [N/mm2], tensile strength is determined by dividing measured value of force by cross-sectional area.

- Abrasion resistance test – abrasion resistance resists mechanical wear, which means that the higher the value the better it is for the structure; Abrasion resistance is connected with compressive strength of concrete and strong concrete is more abrasion-resistant, so both of the tests can be correlated.

Validation

Specific methods used for validation of results depending on the technique

Quantification of the error

Quantitative or qualitative evaluation

Detection accuracy

According to standard EN12504-1:2000, the accuracy and reproducibility of test results are not assessed.

Advantages

Used core samples are qualitatively better material than those from the laboratory, because they contain all potential defects resulting from various technological and transport situations or climatic influence. Testing the strength of hardened concrete is particularly useful, because the quality of the concrete in structure depends to a large extent on this property. Based on the static strength tests it is possible to conclude if the analysed bridge structure can still transfer utility loads with accordance to norm.

Disadvantages

All methods induce damage to the structures which can cause risk during works and require repairs. In practical situation drilled sample taken may not be a good representation of the entire structure, which leads to inaccuracies and doubts.

Possibility of automatising the measurements

Mechanical tests cannot be performed without the presence of the operator for now, however the measurements can be automated with use of most advanced equipment enabling reduce of the time needed to perform tests.

Barriers

There is a need to develop a base of correlation curves for various typical concrete groups and different dimensions to study degradation process in whole structures accurately.

Existing standards

- EN 12390-3:2001 Testing hardened concrete - Part 3: Compressive strength of test specimens

- EN 12390-1:2001 Testing hardened concrete - Part 1: Shape, dimensions and other requirements for specimens and moulds

- EN 12390-4:2001 Testing hardened concrete - Part 4: Compressive strength - Specification for testing machines

- EN 12504-1:2002 Testing concrete in structures

- ASTM C801-98 STM for Determining the Mechanical Properties of Hardened Concrete under Triaxial Load

- ASTM C900-94 STM for Pullout Strength of Hardened Concrete

- AS 1012.14-1991. Method of Testing Concrete - Method for securing and testing cores from hardened concrete for compressive strength

- BS 1881: pt. 4, “Methods of testing concrete for strength”, British Standards Institution, London

- BS 1881: Part 121: 1983 - Method for Determination of Static Modulus of Elasticity in Compression

- BS 1881: Part 120: 1983 - Method for Determination of Compressive Strength of Concrete Cores

- BS 1881: Part 116: 1983 - Method for Determination of Compressive Strength of Concrete Cubes

- ASTM C944 (2012), Standard test method for abrasion resistance of concrete or mortar surfaces by the rotating-cutter method, ASTM International, West Conshohocken, 5pp.

Applicability

Relevant knowledge fields

Civil engineering:

- quality control of concrete

- production quality of concrete

- historical building structural assessment

Performance Indicators

- rupture,

- deformation,

- holes,

- wire break,

- loss of section,

- obstruction/impeding,

- displacement,

- cracks,

- stirrup rupture,

- displacement,

- reinforcement bar failure/bending,

- tensioning force deficiency,

- prestressing cable,

- debonding,

- delamination.

Type of structure

- bridge,

- tunnel,

- road.

Spatial scales addressed (whole structure vs specific asset elements)

- steel-concrete spans,

- concrete bridge supports,

- abutments,

- bearings,

- pillars.

Materials

- concrete,

- steel,

- polymer,

- composite,

- silicate,

- nanocomposite,

- metal,

- alloys.

Available knowledge

Reference projects

Not applicable.

Other

MATEST Specimen Cutting Machines

MATEST Elastic Modulus Determination

Prescott Instruments Dynamic Testing

Central Road Research Institute Abrasion Testing Machine

Bibliography

- Alexander, M. (1985). Towards standard test for abrasion resistance of concrete. Report on a limited number of test studied with a critical evaluation. Materials and Structures 18, 106, pp. 297-307.

- C. Jeng, M. C. (2019). Torsion experiment and cracking-torque formulae of hollow presstresed concrete beams. . Materials Science, Engineering Structures .

- EN 12504 - Concrete testing in structures - Part 1: Core drilling - Cutting, evaluation and compressive strength testing. (2001).

- EN 13791:2007 Assessment of concrete compressive strength in structures or in structural elements. (2007).

- Eric P. Koehler, D. W. (2003). Summary of Concrete Workability Test Methods. (ICAR 105-1). Aggregates Foundation for Technology, Research, and Education . Texas: International Center for Aggregates Research, The University of Texas at Austin.

- Francois, D. (2008). Structural Components - Mechanical Tests and Behavioral Laws. John Wiley & Sons, Inc. .

- Gordon, P. (2011). Low cycle fatigue behaviour of concrete with recycled concrete aggregates. Faculty of California Polytechnic State University.

- H.W. Fritz, E. E. (1990). Mechanical Tests for Bituminous Mixes. Characterization, Design and Quality Control . Proceedings of the Fourth International Symposium RILEM Technical Commitee 101-BAT . Budapest: Chapman and Hall.

- Indelicato, F. (1997). Estimate of concrete cube strength by means of different diameter cores: A statistical approach. Materials and Structures vol. 30, no 4, pp. 131-138.

- J.R. Del Viso, J. C. (2008). Shape and Size Effects on The Compressive Strength Of High Strength Concrete, Cement And Concrete Research 3 (2008) 386-395;. Cement And Concrete Research 3 , 386-395.

- Jarominiak, A. (1999). Podstawy utrzymania mostów. Oficyna Wydawnicza Politechniki Rzeszowskiej.

- Johannes Haufe, A. V. (2019). Tensile strength of concrete exposed to sulfate attack. . Materials Science, Cement and Concrete Research .

- Liu, T. C. (1981). Abrasion resistance of concrete. ACI Journal, pp. 341-350.

- Malhorta, V. M. (1977). Concrete strength requirements - cores versus in-situ evaluation. Journal of American Concrete Institute vol. 74, no 4, pp. 163-172.

- Michalak, E. (2016). Diagnostics of the concrete bridges in a view of European Union Norms. Archives of Institute of Civil Engineering no. 21.

- Moczko, A. (2008). Ocena wytrzymałości betonu na ściskanie w konstrukcjach na podstawie badania odwiertów rdzeniowych w świetle nowej normy europejskiej. Budownictwo, Technologie, Architektura, pp. 50-55.

- Neville, A. M. (2000). Właściwości betonu. Kraków: Polski Cement Sp. z o. o.,.

- PN-EN 12390 - Część 3:2001 Badania betonu - Wytrzymałość na ściskanie. (2001).

- Reichard, B. (2015). Uniaxial tensile testing technique to obtain softening response of ultra-high performance concrete under confining pressures. Materials Science .

- S.T. Yi, E. Y. (2006). Effect Of Specimen Sizes, Specimen Shapes and Placement Directions on Compressive Strength of Concrete. . Nuclear Engineering And Design 236, pp. 115-127.