Micro Electro-Mechanical Systems (MEMS) - Clinometers

Goal(s)

Main objective

MEMS sensors include a variety of transducers based on special micromachining of silicon. This allows to create sensor families having tunable features, according to the specific needs.

One application of MEMS sensors are Clinometers. They derive from MEMS accelerometers and measure the inclination with respect to the horizontal axis. For this reason, they are useful to analyse structures static behaviour.

Description

Functioning mode

MEMS Clinometers measure acceleration along a single axis or two normal axes to give the acceleration vector.

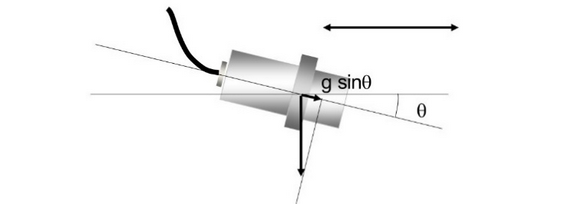

MEMS Clinometers are g sensitive: pitch or roll cause a change in the projection of gravity along the sensitive axis.

As a fraction of gravity is sensed, MEMS clinometers only work for rotations around axes lying in the horizontal plane, while rotations around a vertical axis do not produce any measurable change.

The output is proportional to sinθ, where θ is the angle between the sensing axis and the horizontal plane: this means that the output is not linear and that sensitivity changes according to the same angle θ the clinometer is sensing. Some facts are easily noted: For small rotations around θ=0 deg the calibration curve can be linearized and the maximum sensitivity is achieved

- For angles close to θ=90 deg the sensitivity (proportional to cosθ) tends towards 0 and linearization is not really possible as the calibration curve rate of change is higher than around zero.

Types

There are several types of MEMS clinometers, all provided as an Integrated Circuit with some conditioning electronics on a board. MEMS clinometers differ in parameters settings values, such as: Full Scale (FS): range of acceleration values that can be measured

- Resolution: minimum detectable change in acceleration, expressed in [mg]

- Sensitivity: also known as gain, is the output change per unit of input acceleration.

MEMS clinometers can be single axis or dual axis.

Process/event to be detected or monitored

MEMS clinometers are useful to analyse structures static behaviour. Through pitch and roll measurements they allow the detection of structures elements deformations, highlighting the appearance of eventual damage process, of brittle or plastic nature.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical and chemical properties, relative displacements of the two sides of a crack, etc.).

MEMS clinometers, returning tilt, can be used to measure structures deformations and relative displacements between different structural elements.

Induced damage to the structure during the measurement

No damage induced.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

The design of MEMS accelerometers makes them g-sensitive, this means that their lower bound can extend to 0 Hz, which means capability to measure static or quasi static quantities. Therefore, they are suitable to measure tilt, as the projection of gravity along the measurement axis.

MEMS clinometers can be employed for both short-term and continuous testing; besides, they can be used to describe the behavior of both local structural elements and the global structure.

Measurement range

As accelerometers work below resonance, the MEMS accelerometer performances depend upon the natural frequency of the silicon structure, which can be designed to reach bandwidths from some hundreds of Hertz up to some thousands, for sure redundant for monitoring applications, mainly requiring low frequency ranges and low full scales.

The full scale can also be adjusted thanks to a specific electronic hardware: full scale for the MEMS commonly adopted in monitoring applications can range from fractions of gravity up to some g, even if it is not so uncommon to have full scales of several hundred g, for specific applications, not related to monitoring.

Measurement accuracy

MEMS accelerometers can provide an analog output, though these are not so common today, or an already digitized output; they require a power supply typically in the range 0-5 V and also the output is within the mentioned range.

Clinometers have a measurement accuracy changeable based on their setted parameters (FS, etc.). Maximum sensitivity is achieved for low angle, around the horizontal axis.

The measurement can be affected by errors due to temperature drifts; for compensating this error it is advisable to have an on-board temperature sensor in the clinometer case itself.

Background (evolution through the years)

In the second half of the 1950s, the first papers regarding MEMS technology were published (C.S. Smith, 1954), describing piezoresistive effects in silicon and germanium. First MEMS applications are related to silicon pressure sensors, which commercialization started in the USA at the end of the 1960s. The technology development was very fast, thanks to improvements in silicon processing and in micromachining. Small, rugged and inexpensive devices with always increasing performance were produced, ranging in different categories: accelerometers, strain gauges, pressure sensors, microphones, gyroscopes, etc. Fields of application of the technology, as consequence, increased through the years: MEMS sensors are applied in the automotive, medical, aerospace, automation industry. Accelerometers technology is continuously evolving, advanced surface micromachining techniques allow them to sense in one, two or three axes and thanks to always improved performance, their market is expanding and it is expected to grow rapidly in the future.

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

Procedures for defining layout of the survey

Sensors layout should be carefully designed according to the phenomenon to be analysed and/or monitored. It would be advisable to have one sensor on each key node of the structure and on each relevant structural element, so that any deformation of the structure can be detected.

Sensibility of measurements to environmental conditions

MEMS accelerometers measurements can be influenced by environmental conditions, especially by temperature and during long-term/continuous testing. For this reason, it is advisable having an on-board temperature sensor, so that eventual temperature drift can be compensated.

Preparation

Procedures for calibration, initialisation, and post-installation verification

MEMS clinometers calibration aim to obtain sensors sensitivity at different tilts. Procedure usually consists in rotating the device through a known set of angles and measuring the acceleration output given by the sensor. Through a subsequent analysis, comparing sensor and theorical measure, the calibration curve is obtained.

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Not applicable.

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Not applicable.

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Not applicable.

Criteria for the successive surveying campaigns for updating the sensors. The campaigns include: (i) Georeferenced frame, i.e. the global location on the bridge; (ii) Alignment of sensor data, relative alignment of the data collected in a surveying; (iii) Multi-temporal registration to previous campaigns; and (iv) Diagnostics.

Not applicable.

Reporting

Lifespan of the technology (if applied for continuous monitoring)

MEMS lifespan can vary between 2 and 5 years.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

MEMS clinometers output are accelerations, expressed in a measure of gravity (g) or, if the measures are already calibrated, in degrees.

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

MEMS accelerometers output consists in a measure of tilt, along one or two axis.

Validation

Not applicable.

Detection accuracy

Not applicable.

Advantages

MEMS accelerometer main advantages are:

- Low-cost technology.

- Applicable in a continuous SHM system.

- Easy transportation and installation

- Small size

- Depending on the application, sensors can be set with different parameters.

Disadvantages

- High measurement accuracy only around small angles.

- Only rotations around axis laying in the horizontal plane can be measured.

Possibility of automatising the measurements

A sensors network made by MEMS can be automatised by means of a gateway that manages sensors acquisition. In this way, sensors acquisition can depend on different rules: it can be continuous in time, limited to predefined intervals in a journey, etc.

Barriers

Existing standards

Applicability

Relevant knowledge fields

- Civil Engineering and Structural Health Monitoring

- Automotive Application

- Industrial Application

- Medical Application

Performance Indicators

- Deformation

- Loss of section

- Reinforcement bar failure/bending

Type of structure

- Bridges

- Tunnels

Spatial scales addressed (whole structure vs specific asset elements)

Materials

Available knowledge

Reference projects

Other

Bibliography

- Angell, J.B., Terry, S.C., Barth, P.W. (1983), Silicon Micromechanical Devices, Scientific American, Vol. 248, pp. 44-55.

- Banks, D. Introduction to Microengineering, http://www.dbanks.demon.co.uk/ueng/what.html

- Charles R. Farrar, K. W. (2012). Structural Health Monitoring: A Machine Learning Perspective.

- De Los Santos, H.J. (1999). Introduction to Microelectromechanical (MEM) Microwave Systems, Artech House Microwave Library, Artech House, Boston, MA.

- Fraden, J. (2010). Handbook of Modern Sensors: Phisics, Designs, and Applications.

- Feynman, R. (1992). There’s Plenty of Room at the Bottom, Journal of Microelectromechanical Systems, Vol.1, No.1, pp. 60-66.

- Kempe, V. (2011). Inertial Mems: Principles and Practice.

- Kovacs, G.T.A. (1998). Micromachined Transducers Sourcebook, McGraw-Hill, New York, NY.

- Madou, M. (1997). Fundamentals of Microfabrication, CRC Press, Inc., Boca Raton, FL.

- Muller, R.S., Howe, R.T., Senturia, S.D., Smith, R.L., and White, R.M. [Eds.] (1991). Microsensors, IEEE Press, New York, NY.

- PRIME Faraday Partnership (2002). An Introduction to MEMS.

- Richard S. Figliola, D. E. (2015). Theory and Design for Mechanical Measurements, 6th Edition.

- Soloman, S. (2010). Sensors Handbook.

- Steve P. Beeby, G. E. (2004). MEMS Mechanical Sensors (Microelectromechanical Systems Series).

- Thomas Beckwith, R. M. (2006). Mechanical Measurements 6th Edition.

- Trimmer, W.S. (1997). Micromechanics and MEMS: Classic and Seminal Papers to 1990, IEEE Press, New York, NY.