Surface measurements

Goal(s)

Main objective

Bridge infrastructure monitoring technologies are crucial for predicting the effects of the damages and preventing potential accidents. The advantages of the multi-scale data collection cannot be disregarded for future infrastructure maintenance purposes, especially the possibility of real-time data storage, remote control of facilities from different locations, and enabling and sharing research results on a large scale. However, multi-scale data collection requires a specific system configuration and operational knowledge of a professional level. In addition, it requires significant financial expenses on the equipment, power supplies, training, and maintenance over time and under different environmental conditions.

Surface measurements can be used on concrete samples or concrete structures directly on the facility. Mostly used techniques are Schmidt hammer test, Windsor probe test or pull-out test, which enable to identify of important quality characteristics of different structural elements of bridges such as compressive strength and hardness of selected elements. If performed regularly, prevent the degradation processes to expand and accelerate and thus allow the implementation of appropriate preventive steps.

Description

Functioning mode

- Schmidt hammer test/Rebound test – a hammer is pushed against a concrete sample and its body is allowed to move away from the concrete until the handle connects the hammer mass to the plunger. The plunger is placed perpendicularly to the surface of concrete and the body is slowly pushed towards the concrete. This movement extends the spring which holds the mass to the body. In the maximum extension of the spring – the latch releases, mass is pushed by the spring. Then the mass hits the shoulder of the plunger and rebounds. Slide indicator goes with hammer mass and stops at the maximum distance after rebounding. The plunger is locked, and the rebound number can be read from the scale of the tool.

- Windsor probe test/Penetration test – usually the system consists of a digital measuring unit with a memory for data storage, probes and charges; the suitable probe is loaded into the driver, the driver is placed on the actuating template and fired, probe is located at the corners of a fixed triangle. By the electronic device, there are few parameters selected such as type of concrete, units, aggregate hardness. Every three individual tests are averaged automatically, and the results can be read from the screen.

- Pull-out test – before the measurement a metal anchor is concreted in the inspected area and then extracted to estimate the resistance in the tested place; the equipment is then pulled to the designated stress load; The anchor is concreted in the structure and expanded in a specially cut hole. During the measurement, the anchors are pulled out of the concrete by a hydraulic actuator, which presses against the concrete surface through a stop ring. Two functioning modes can be highlighted:

- LOK-test – when the anchors are pre-concreted during concreting the structure, used for new constructions.

- CAPO-test – when the anchors are placed into the drilled measurement holes in existing constructions.

Types

- Schmidt Hammer test – from the point of view of the measured sample Schmidt hammers can be divided into two categories:

- hammer type N – used in case of walls and other structural elements with thickness more than 10 mm,

- hammer type L – used in case of materials with lower thickness, which are subjected to damage due to brittleness; there are other impact parameters than in N-type.

- for fresh, low-strength concrete – 1-5 MPa, 5-10 MPa.

- normal concrete – 10-30 MPa, 30-70 MPa.

- high-strength concrete – 70 – 100 MPa.

- Windsor probe test – depending on the application there are two types of equipment used:

- Windsor system with a probe for lightweight, low density concrete.

- Windsor system with a probe for standard mix designs

- silver probes for high performance concrete with strength up to 110 MPa.

- golden probes for concretes with strength below 110 MPa.

- low power,

- standard power .

- Pull-out test – usually the system consists of a hydraulic jack, pressure gauge for precise readings over a wide load range, bearing ring and pull-out inserts – contained in a carrying case. There are different adapters for different fixings and tests available. The load can be applied mechanically or hydraulically. Hydraulic systems are used for high loads.

Process/event to be detected or monitored

- Schmidt Hammer test – change of the hardness of the surface in different intervals of time, due to changes in surface hardness, surface of the concrete can be mapped, and corrosion can be detected.

- Windsor probe test – change of concrete compressive strength of a structure by driving a probe into the concrete with a known amount of force; monitoring of the strength for rehabilitation as concrete ages.

- Pull-out test – change of compressive strength in the structure and monitoring of potential strength and durability problems.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical and chemical properties, relative displacements of the two sides of a crack, etc.).

- Schmidt Hammer test – average rebound value R; compressive strength; hardness value.

- Windsor probe test – compressive strength; hardness value.

- Pull-out test - force [kN] required to pull a shaped steel rod out of the hardened concrete.

Induced damage to the structure during the measurement

- Schmidt Hammer test – during on-site measurements usually there are no damages to the structure or slight scratches, under laboratory conditions, it is necessary to prepare the samples by drilling holes in inspected areas.

- Windsor probe test – during on-site measurements after the penetration at least 8 mm holes are present in the structure, under laboratory conditions it is necessary to prepare the samples by drilling holes in the inspected area.

- Pull-out test – after the penetration leaves at least 8 mm holes in the structure, involves breaking the concrete, under laboratory conditions it is necessary to prepare the samples by drilling holes in the inspected area.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

- Schmidt Hammer test – static and local measurement; short-term.

- Windsor probe test – static and local measurement; short-term.

- Pull-out test – static and local measurement; short-term.

Measurement range

- Schmidt Hammer test: 10 – 70 MPa for resistance to pressure.

- Windsor probe test: 10 – 70 MPa depending on the mixture of concrete.

- Pull-out test: 5 – 130 MPa; load range: 0 – 255 kN.

Measurement accuracy

- Schmidt Hammer test: 2.2 +/– 0.1 J for impact energy.

- Windsor probe test: compressive strength above 3.62 MPa can be detected.

- Pull-out test: load is applied with 0.2 – 0.5 kN accuracy.

Background (evolution through the years)

The Schmidt hammer for concrete testing was developed by Ernst O. Schmidt and introduced to the market in early 1950. It is the most widely used measuring device for quick, non-destructive assessment of the condition of a concrete structure. Its use expanded over the years of testing. In 1938 there were first publications about in-place testing of concrete by pull-out tests in the Soviet Union. In 1970 pull-out test was widespread and used as a standard practice. The Windsor Probe test was developed in 1960 between the New York Port Authority and the Windsor Machine Company .

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

- Schmidt Hammer test – rough surfaces do not give reliable results and should be avoided – the surface of the measured area (or sample) should be smooth; If the test is carried out on the sample any movement caused by the impact of the hammer will result in a reduction in the rebound number. In such cases, the member has to be rigidly held. The rebound numbers are lower for well-cured air-dried samples than for the same ones tested after being soaked in water and tested in the saturated surface dried conditions.

- Windsor probe test – in order to measure correctly and to avoid damaging the surface on which the measurement is carried out, it is recommended to use special frames to relieve the structure from the load; to obtain accurate results, it is necessary to know the hardness of the aggregate – in situations in which there is no historical data about the mixture of concrete used there are procedures to obtain the hardness value such as performing Mohs’ test; In order to get a good reading,

- - maximum spacing between probes = 175 mm

- - minimum spacing between probes = 100 mm

- - minimum spacing between concrete and the edge of a concrete surface = 100 mm

- Pull-out test - The test should be preceded by the location of the reinforcement, the removal of corroded concrete of corroded concrete and the smoothening of the surface. The axis of the anchor must be at least 100 mm from the edges and corners of the element and 50 mm from the reinforcement inserts. On a single element, tests are performed in at least 5 measurement places.

Procedures for defining layout of the survey

For all the methods above the layout out of the survey should be considered with use of available standards and the availability to reach specific parts of the construction by the operator.

Sensibility of measurements to environmental conditions

Preparation

Procedures for calibration, initialisation, and post-installation verification

- Schmidt Hammer test – hammer should be calibrated using a calibration test anvil supplied by the manufacturer. Twelve readings should be taken, eliminating the highest and lowest, and taking the average of the ten remaining.

- Windsor probe test – according with the manufacturer manual, usually serviced and calibrated on annual basis

- Pull-out test – calibration should be done at least once a year; recalibration should be made whenever there is a doubt on accuracy of the measurement. Procedure of calibration is given in ASTM C 900.

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Not applicable.

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Reporting

- Schmidt Hammer test – example of the report has been shown below; also reports can be automatically created by phone applications in advanced hammers technology.

| REPORT FROM REBOUND TEST | Operator:…. | ||||||||||||

|

Date of the inspection: ...................... Model of the hammer and type: ....................... Object/Structure identification: ...................... Element of the construction: ...................... Age of concrete: ...................... |

Standard rebound average value on steel anvil:

…………………… (80+/-2) | ||||||||||||

| Degree | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average | Standard deviation | |

| 1 | 0⁰ | ||||||||||||

| 2 | 0⁰ | ||||||||||||

| 3 | 0⁰ | ||||||||||||

| 4 | 0⁰ | ||||||||||||

- Windsor probe test – data from the tests are stored in the memory and can be transferred on the computer.

| REPORT FROM WINDSOR PROBE TEST | Operator:…. | |||||

|

Date of the inspection:...................... Model of the system and type of probe :............... Object/Structure identification:……………… Element of the construction:……………………… Age of concrete:........................ Type of concrete........... |

||||||

| Tested Area | Aggregate | Mohs Number | Cure days | Probe Certification Number | Compressive Strength | |

| 1 |

| |||||

| 2 | ||||||

| 3 | ||||||

- Pull-out test - example of the report has been shown below:

| REPORT FROM PULL-OUT TEST | Operator:…. | |

|

Date of the inspection:...................... Model of the device:............... Object/Structure identification:……………… Element of the construction:……………………… Age of concrete:........................ |

||

| Concrete type and identification of the sample | Pull out result | Strength |

Lifespan of the technology (if applied for continuous monitoring)

These techniques do not offer continuous measurement.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

- Schmidt Hammer test – list of numbers with rebound values; in advanced Schmidt hammers the results can be storage, evaluated in phone application (e.g. Schmidt App) and exported as txt, Excel file etc..

- Windsor probe test – list of numbers with compressive strength values.

- Pull-out test – force value needed to pull out the steel anchor for selected tested areas.

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

- Schmidt Hammer test – for surfaces that are subjected to damage processes such as corrosion and carbonation the rebound number will be significantly higher than for the non-affected surfaces.

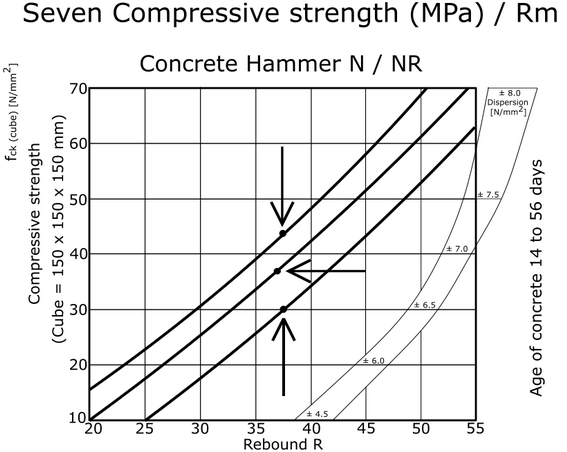

- For estimation of the compressive strength correlation curves are used, usually added by manufacturer to the manual which show the relationship between the rebound number and compressive strength. However, in advance equipment data are evaluated automatically. Example of the correlation curves is shown below:

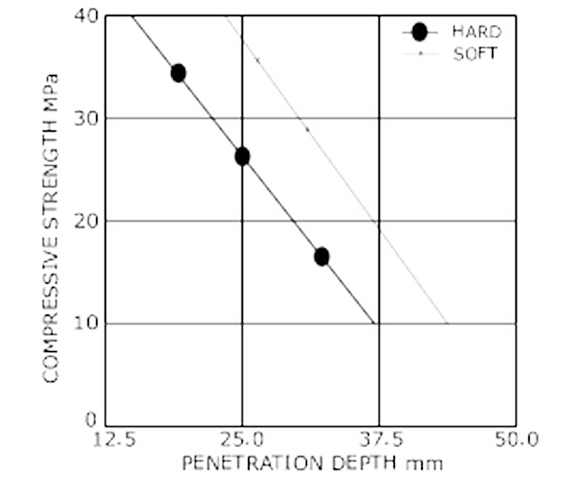

- Windsor probe test – based on the surface hardness of a concrete element – hardness is used to estimate concrete strength. The penetration resistance of concrete is computed by measuring the exposed length of probes driven into concrete. In order to estimate concrete strength, it is necessary to establish a relationship between penetration resistance and concrete strength. Relationship must be established for a given test apparatus, using similar concrete materials and mixture proportions as in the structure. Statistical methods can be used for developing and using the strength relationship.

- Pull-out test – value of force generated by the test is then used to determine the strength parameters of concrete through calibration curves or correlation of the test with other non-destructive testing methods. The individual pull-out test results are converted to equivalent values of compressive strength using the previously established correlation. The mean and standard deviation of the set of pull-out test results are determined.

Validation

Specific methods used for validation of results depending on the technique

Quantification of the error

Quantitative or qualitative evaluation

Detection accuracy

- Schmidt Hammer test – only a test used for estimating the strength of concrete in structure, detection depends on the type of hammer used – there are basic hammers with analogue screens or automatic ones which show greater accuracy by eliminating the error of reading by the operator; reliable in determining whether the exploitation of the structure would still be safe, but it is not used for determination if it is not safe already. In this case additional surveys should be carried out with other techniques.

- Windsor probe test – depends on the type of system configuration used, however useful in assessing the quality and relative strengths of concrete; equally accurate at obtained results on horizontal or vertical surfaces if the probe is at right angles to the tested surface.

- Pull-out test - method can be more than twice as accurate in comparison with non-destructive surveys.

Advantages

- Schmidt Hammer test:

- rapid testing,

- inexpensive equipment.

- Windsor probe test:

- can be used as substitute of core tests,

- light, standard and high-weight concrete strength can be tested,

- high-precision,

- fast and economical,

- no accidental discharge,

- not complicated maintenance.

- Pull-out test:

- good performance on new and old structures,

- easy to install.

Disadvantages

- Schmidt Hammer test:

- estimation of the values only.

- can generate misleading results.

- Windsor probe test:

- leaves holes in concrete, where the probe penetrated,

- damaged area has to be repaired usually,

- can cause minor cracking.

- Pull-out test:

- destructive for the structure

- does not measure the interior strength of the concrete.

- large number of tests needed in different parts of the construction for accurate results.

Barriers Possibility of automatising the measurements

Measurement with Schmidt Hammer and Windsor Probe are automatic, however it is not possible to eliminate the presence of the operator to perform the test for now.

Barriers

No major barriers.

Existing standards

- Schmidt Hammer test:

- EN 12 504-2, ENV 206 Europe

- BS 1881: Part 202: 1986 - Recommendations for Surface Hardness Testing by Rebound Hammer

- ASTM C805-97 STM for Rebound Number of Hardened Concrete, USA

- ISO/DIS 8045 Concrete, hardened - Determination of rebound number using rebound hammer

- BS 4408: pt. 4, BS 1881: part 202, Non-destructive methods of test for concrete - surface hardness methods British Standards Institution, Great Britain

- DIN 1048, part 2 Germany

- NFP 18-417, France

- B 15-225, Belgium

- JGJ/T 23-2011, China

- Windsor probe test:

- ASTM C 803-82, STM for Penetration Resistance of Hardened Concrete

- BS 4408: pt. 4, Non-destructive methods of test for concrete - surface hardness methods British Standards Institution, London

- AS 1012.18-1996. Method of Testing Concrete - Determination of setting time of fresh concrete, mortar and grout by penetration resistance

- ACI 228.1R-03: In-Place Methods to Estimate Concrete Strength

- Pull-out test:

- ASTM C900-94 STM for Pullout Strength of Hardened Concrete

- ISO/DIS 8046 Concrete, hardened - Determination of pull-out strength

Applicability

Relevant knowledge fields

- Civil engineering:

- formwork removal,

- rock testing,

- profiles testing,

- railways,

- commercial buildings,

- airports.

Performance Indicators

- deformation,

- rupture,

- loss of section,

- cracks,

- holes,

- displacement,

- reinforcement bar failure/bending,

- tensioning force deficiency,

- debonding.

Type of structure

- concrete bridges,

- masonry bridges,

- tunnels.

Spatial scales addressed (whole structure vs specific asset elements)

Surface measurements are not designed in a way for specific assets, however it is possible to study various element of a bridges and other facilities. Methods are not suitable for drawing conclusions about whole structure. Most commonly used for parts of bridge like: beams, slabs, columns, piers, abutment walls.

Materials

- concrete,

- steel,

- composites,

- rock,

- paper,

- mortar,

- sand.

Available knowledge

Reference projects

No reference projects.

Other

Manufacturers (Schmidt hammer):

Humboldt Construction Materials Testing Equipment

NDT JAMES INSTRUMENTS - Windsor Probe System