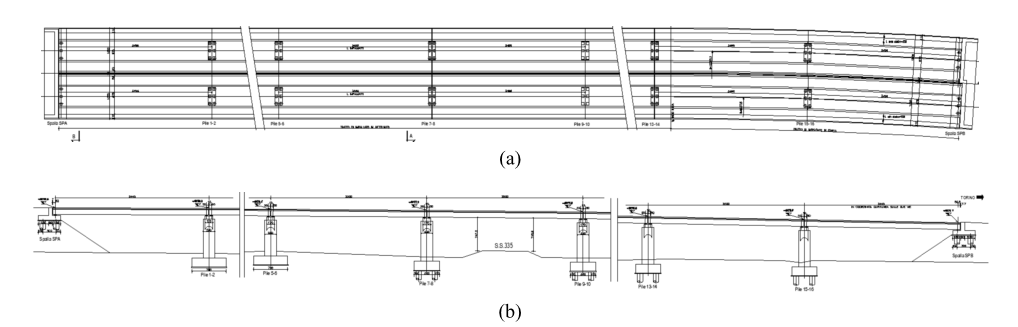

Viaduct SS335 (case study)

Object description

(No object description available.)

Object analysis

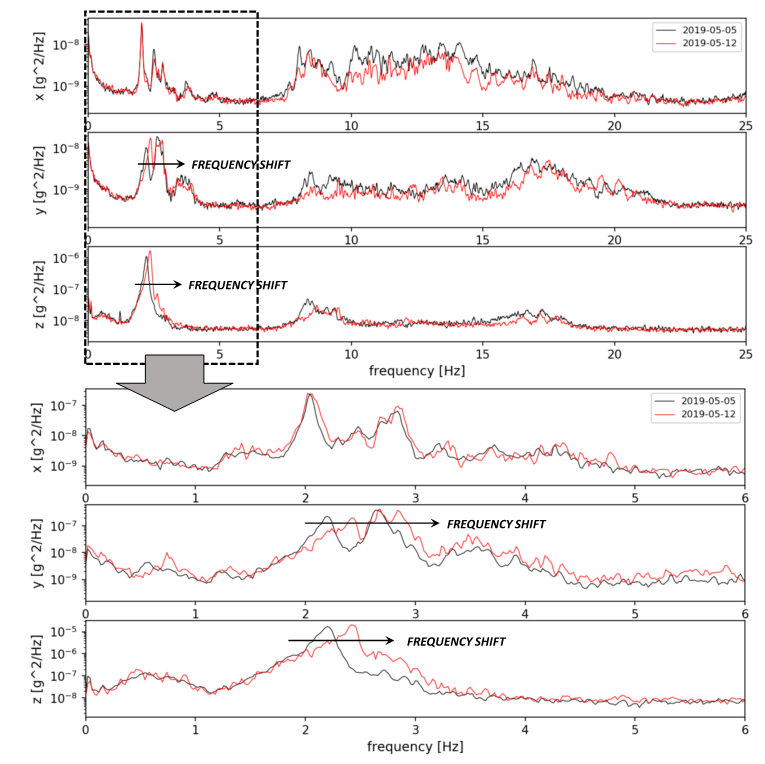

During the strenghtening works the clinometers raw data were analyzed to evaluate the plastic deflection recovery after the external pre-stressing was applied to the deck. Vibration-based damage detection techniques were used to identify the changes in the dynamic response of the system, such as Operational Modal Analysis (OMA) techniques, Power Spectral Density (PSD) and Frequency Domain Decomposition (FDD). A stable peak-picking analysis has been performed to track the natural frequencies evolution in the long-term period. Non-Linear Finite Element Analysis (NLFEA) and a model updating procedure were used to simulate the bridge behavior both in damaged and strengthened state. The FE model was also used to simulate a set of possible damaged scenarios to calculate the thresholds in terms of plastic rotations and frequency shifts for the long-term monitoring.

Object state

Following an inspection, some cracks were found at the inner surface of the slab, due to the failure of a significant number of pre-stressing tendons caused by a diffuse corrosive phenomenon. Strengthening works were necessary, the solution chosen was the adoption of an external pre-stressing system. The Sacertis SHM system installed in April 2019 was developed for both the short and long-term monitoring. Each span is equipped with a chain made by five biaxial MEMS clinometers and five triaxial MEMS accelerometers. The system is completed by two gateways, one per carriageway and a power line communication to connect all the devices to the network. In each sensor box are present a temperature and humidity detectors. Prior information available were: drawings, design documents, results of thorough investigation of the damaged span. A calibrated non-linear FE model based on the static load test and dynamic characterization of the structural response (in both the damaged state and after the strenghtening works) has been used to determine the warning and alarm thresholds levels.

Images

Documents

This case study was contributed by Paola Darò of SafeCertifiedStructure Ingegneria S.r.l.. Last edited by technical staff.