Maintenance strategies

Assessment phase

Maintenance strategies for the assessment phases are described on separate pages:

Engineering practice

Engineering practices are described on separate pages:

Maintenance

Maintenance is one of the intervention options to be considered for life cycle management of structures and plays a major role in seeking the optimum between maximizing performance and minimizing life cycle costs, with due consideration to the suitability perspective. Maintenance is defined as a combination of all technical, administrative and managerial activities performed during the service life of the structure in order to in order to retain or restore its performance and future serviceability at/to the level at which it can perform the required function. In other words, maintenance aims to ensure that assets continue to be able to do what they are designed for and benefit its users, and society at large, now and in the future.

Requirements for maintenance strategies for an asset, or its component parts, should be defined at the time of design (for new structures) or re-design (for existing structures) and should include allocation of the asset to a maintenance class. This should be done on the basis of a number of factors, such as the social and economic importance of the structure, its function, the nature of its design and that of its components, design service life, potential hazards incl. the environmental conditions to which it is exposed, the possible mechanisms of deterioration, the ease of undertaking inspections and maintenance works, together with considerations of cost and impact on third parties and environment.

The typical maintenance class (also referred to as conservation categories) can be classified as follows (fib MC2020, 2022)

- Category A: structures or parts thereof which are to be managed by planned proactive maintenance works and interventions.

- Category B: structures or parts thereof which are managed by reactive interventions.

- Category C: structures or parts thereof for which maintenance works and interventions would be extremely difficult or are not practical.

Examples of structures within the three maintenance classes are (fib MC2020, 2022):

- Category A:

- structures whose deterioration must not be apparent or would be technically unacceptable from a client requirement or technical performance perspective;

- monumental, important or sensitive buildings and structures.

- Category B:

- structures for which remedial measures can be taken once a small degree of deterioration becomes apparent (presumably visually, but potentially with the assistance of NDT / SHM techniques);

- buildings and other common structures.

- Category C:

- structures where it would be difficult economically and/or technically for preventative or remedial measures to be taken, such as foundations, for which direct inspection is so difficult and/or costly that assessment and judgment may need to be made based on information gathered on indirect performance indicators.

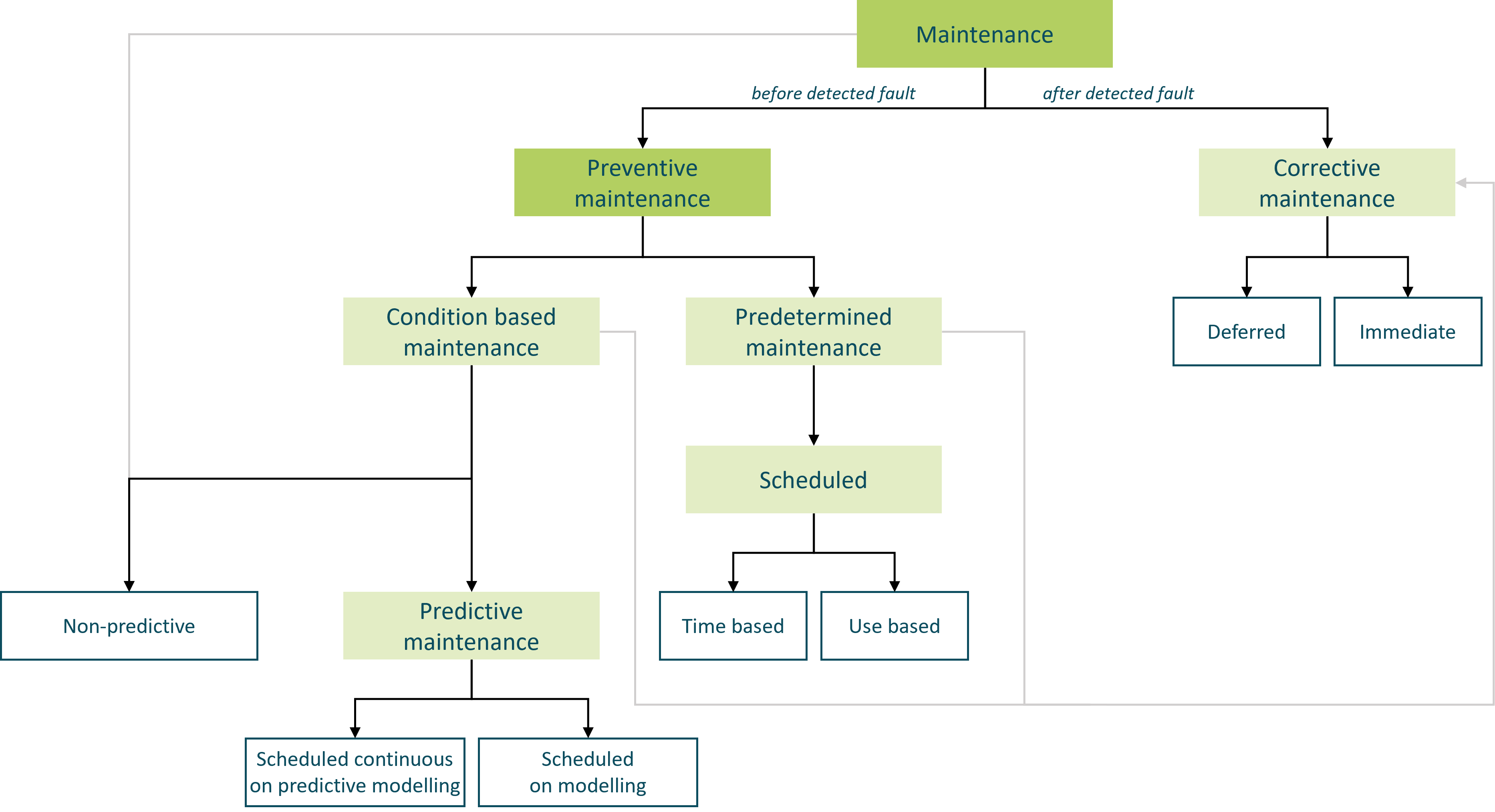

Classification of main maintenance strategies

A maintenance strategy indicates the approach taken in maintaining in relation to a particular risk that may affect the assets performance. A common typology of maintenance strategies highlights differences in terms of:

- acceptance of risk;

- the basis on which maintenance is planned and/or takes place;

- the type of activities required in the strategy (e.g. maintenance, inspection, monitoring).

The table below and figure provide an overview of commonly used maintenance strategies, based on (ISO_13822, 2010).

Corrective maintenance strategies

A corrective maintenance strategy is also referred to as reactive maintenance, failure-based maintenance, or as a strategy of ‘run to failure’. The measures and interventions are aimed at arresting currently active processes which are causing deterioration or damage. Typically, remedial interventions involve some form of treatment or the taking of measures after damage has become apparent, presumably involving visual indications (e.g. cracking or spalling of concrete). Such actions may be required immediately (e.g. emergency repair) or may be deferred to a suitable moment later in time (when acceptable). A corrective maintenance strategy means the asset or component is used to its maximal potential (i.e. the full life time is used) and maintenance is done only when failure demands it. This can be reviewed as a default strategy, but may not be appropriate if failure is associated with unacceptable consequences or non-optimal expenditure of means (e.g. budget).

Preventive maintenance strategies

Contrary to corrective maintenance, preventive maintenance strategies aim at taking (maintenance) action prior to failure occurring, thus avoiding the consequences of that failure. For infrastructure assets, a preventive approach to maintenance is desirable as it enables early identification of issues affecting the condition of the objects, potentially enabling early preventative action being taken to minimize the negative effect on the performance of the infrastructure and, consequently, the overall cost of ownership. A preventive maintenance should be applied to objects and components thereof where it is necessary or desirable that the performance be kept above a specified minimum performance requirement. Logically, this requires knowledge on the probability of failure over time and/or use in order to determine when such (maintenance) actions are required. This is where a further distinction in maintenance strategies can be observed (fib MC2020, 2022).

Predetermined maintenance strategies

In so-called predetermined maintenance strategies, an a priori estimate is made within what timeframe or after what use failure becomes likely. Accordingly, activities set for predetermined maintenance are carried out in accordance with established intervals of time or number of units of use but without previous condition investigation. Intervals of times or number of units of use may be established from knowledge of the failure mechanisms of the item. Such estimates are based on databased, experience, etc. Based on this, a suitable moment for maintenance is picked (maximal use time within accepted risk levels). Maintenance interventions are thus planned accordingly.

Condition-based maintenance strategies

Condition-based maintenance strategies rely on (condition) information being obtained during use of the asset with the aim to better estimate when failure might occur, and when maintenance is required. In practice, a difference may be observed in how the information obtained during the use of the assets is used. For example, the observed condition can be compared to a set of e.g. criteria, thresholds, or limits. These criteria are determined based on the likely progression of condition or performance over time. If the observed condition is within acceptable bounds, no maintenance is performed. If the condition is not within acceptable bounds, this means maintenance is required and should be planned accordingly.

This may be referred to as non-predictive condition-based maintenance, as making a case specific prediction is not being made. Predictive condition-based maintenance would then refer to a strategy where information obtained through the life cycle is used to make or update a prediction of the future condition or performance. Appropriate moments for maintenance actions are based on that prediction. The predictive condition-based maintenance is an expansion of the non-predictive condition-based maintenance. The predictive condition-based maintenance entails prescribed criteria related to one (or more) condition thresholds to enable decisions about interventions based on a forecast derived from repeated analysis or known characteristics and evaluation of the significant parameters of the degradation of the item. One of the main differences between non-predictive and predictive condition-based maintenance lies in the data being analysed. While the predictive maintenance strategy relies on combination of condition monitoring and/or inspection and/or testing and analyses the past and actual condition data to estimate future condition development, the non-predictive maintenance strategy relies on historical experience, averages, and life expectancy statistics to predict when maintenance activities will be required.

Predictive condition-based maintenance strategies

The predictive condition-based maintenance strategy therefore looks for physical evidence that a failure is occurring or is about to occur. It is important to realize that this maintenance strategy is aimed at intervening before the failure occurs, on the premise that this is more economical and should have less of an impact on availability. The predictive maintenance approaches need to be underpinned by sound reliability principles and understanding of the phenomena. Furthermore, it should be mentioned that ‘condition’ may be interpreted broadly in this sense as it may include various type of information including condition, performance, properties of the asset, use, etc.

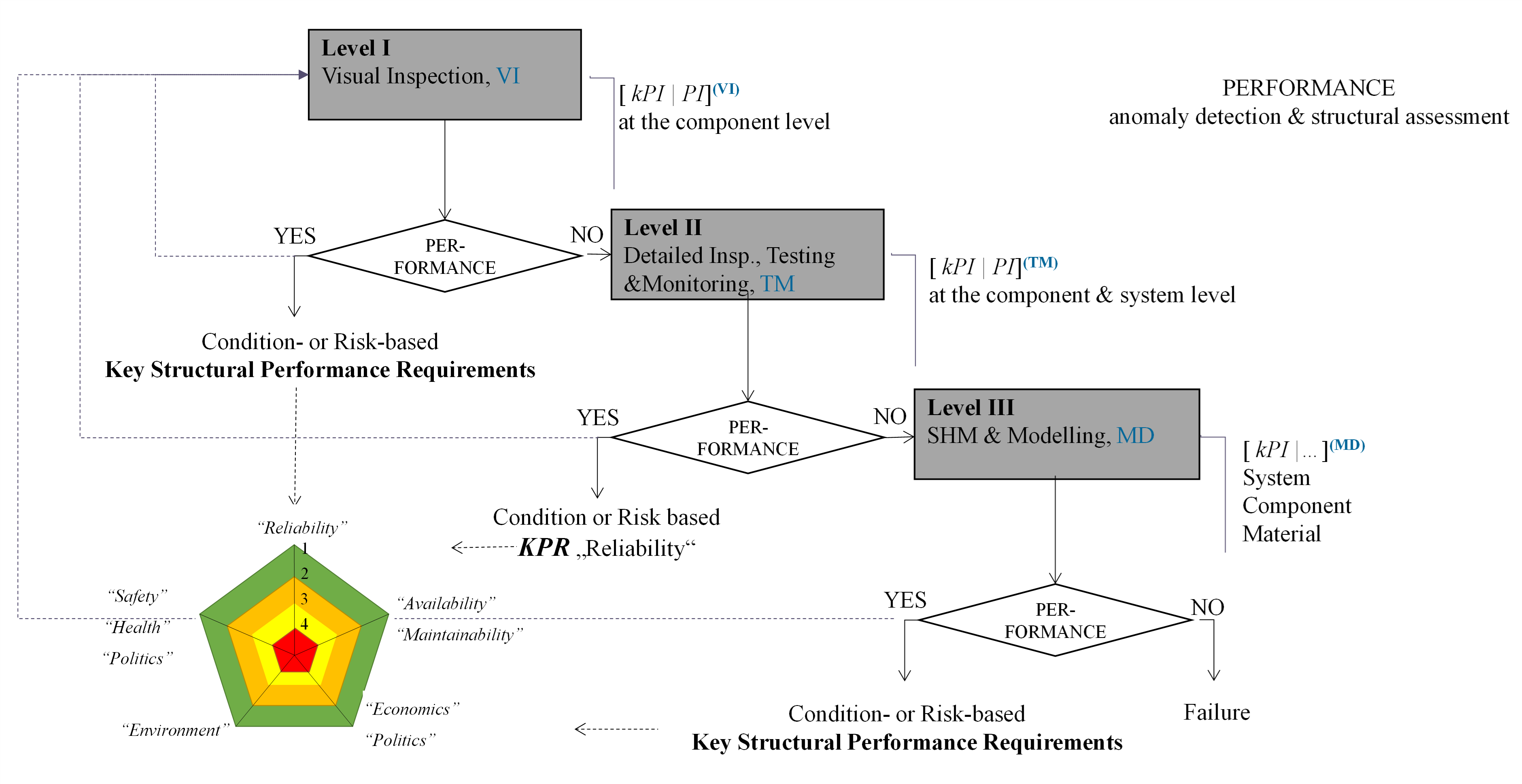

Condition based maintenance assessment phases

In (IMSAFE, 2022) [9.2], a proposal was made for the implementation of performance indicators and key performance indicators in assessment phases. According to (IMSAFE, 2022) ch 9.2 breaking down the performance assessment of a structure or any other facility into a minimum of three phases is reasonable.