Water resistance - Absorption test

Goal(s)

Main objective

Concrete structures are exposed to different weather conditions, soil, water and deicing agents. Crucial contribution to the deterioration processes in bridges or tunnels is assigned to water influence. Water works not only by reacting directly to reinforced concrete structure materials, but mainly by activating the chemicals present in the environment causing chemical reactions to progress. Water resistance measurement test is used as a characterization of durability of concrete elements and durability of the surface protections.

Measurement of water resistance allows to determine the space of pores and absorption rate in the concrete and should not be mistaken with a water penetration test since absorption and permeability values can be uncorrelated with each other.

Method of water absorption is widely used in determination of the effectiveness of hydrophobic surface agents used in securing building materials from the influence of water .

Description

Functioning mode

In water absorption test, the cut out samples from the structure are dried in an oven for a specified time and temperature (usually 70±5)°C and then placed in a desiccator to cool. Immediately upon cooling the specimens are weighed. The material is then emerged in water at agreed upon conditions, often 23°C for 24 hours. After that time samples are removed, patted dry with a lint free cloth, and weighed. Sorption depends on both the capillary pressure and effective porosity. Capillary pressure is related to the pore size and effective porosity refers to the pore space in the capillary and gel pores. In addition, different pore size leads to different capillary pressure, and capillary pressure of concrete can be calculated by the average pore size .

Types

Water absorption test can be divided in four types:

- in laboratory:

- internal water absorption observed – sample of concrete is fully submerged into water:

- surface water absorption observed – sample of concrete is placed on the support creating a contact surface with water:

- on-site:

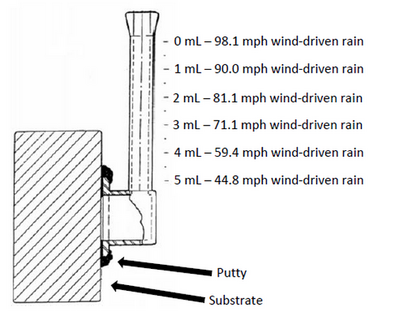

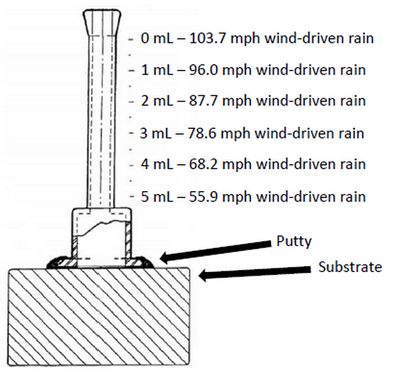

- measurement of the vertical transport of water and resistance to wind-driven rain penetration with an apparatus mounted on the surface under low pressure:

- measurement of the horizontal transport of water and resistance to wind-driven rain penetration with an apparatus mounted on the surface under low pressure:

Process/event to be detected or monitored

The test is used to detect increase in the mass of a specimen resulting from absorption of water as a function of time when only one surface of the specimen is exposed to water.

In case of on-site measurements the volume of water absorbed by a material within specified time period is detected.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical and chemical properties, relative displacements of the two sides of a crack, etc.).

Physical quantity measured is an increase of the mass of the sample or volume of water absorbed due to the capillary absorption of water on the surface or through the volume as a function of time.

Induced damage to the structure during the measurement

Damage is induced during initial stage when drilling in the structure to collect the samples.

In – case of on-site measurement no damage is induced or minor damage in process of mounting the measurement tubes.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

Measurement range

Measurement accuracy

Background (evolution through the years)

In general the water absorption test has been widely used in different industries and fields such as geology, material sciences, textiles etc. to test rate of absorption of water when the desired properties must be maintained due to different requirements .

In civil engineering most of the works concerning the water absorption test were focused on the effectiveness of the surface protection systems for concrete. In 2000 there was introduced polish norm concerning the products used for thermal insulation, defining the test procedure for determination of the water absorption during long-term immersion .

Current norm concerning the absorption test was introduced in 2019 - ISO 16535:2019-08, which includes two types of absorption test, equipment and procedures. It is used for thermal insulation products. Two methods are given in this document:

- method 1: Partial immersion;

- method 2: Complete immersion.

Water absorption with prolonged partial immersion is intended to simulate water absorption caused by prolonged exposure to water.

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

- concrete - cubic samples 100 mm x 100 mm,

- stone – cubic samples 70 mm x 70 mm or 50 mm 50 mm,

- cement-lime – bars 40 mm x 40 mm x 160 mm.

Procedures for defining layout of the survey

- collection of the sample from the place of interest, depending on the material – choice of the dimensions of the samples,

- drying of the samples and cooling to ambient temperature (20°C),

- measurement of the dimensions of the samples,

- placement of the samples in the cuvette with water an registering the hour,

- covering the cuvette with foil to avoid evaporation from the samples,

- after specified intervals – removing the samples, delicate drying and weighting directly after taking out,

- inserting the sample again in the cuvette until next weighting period or removal of the sample,

- determination of the mass change and water absorption rate from the formula,

- conclusions.

Sensibility of measurements to environmental conditions

Preparation

Procedures for calibration, initialisation, and post-installation verification

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Criteria for the successive surveying campaigns for updating the sensors. The campaigns include: (i) Georeferenced frame, i.e. the global location on the bridge; (ii) Alignment of sensor data, relative alignment of the data collected in a surveying; (iii) Multi-temporal registration to previous campaigns; and (iv) Diagnostics.

Reporting

Example of the report table after water resistance test is shown below:

| Sample identification

|

Dimensions | Concrete composition (if known) | Temperature of drying | Duration of drying | Weight after drying | Soaking time | Weight after soaking | Absorptivity

[%] |

| 1 | ||||||||

| 2 | ||||||||

| 3 |

Lifespan of the technology (if applied for continuous monitoring)

Water resistance test is not used as for continuous monitoring.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

Final output of the test is the calculated absorption coefficient as a number for an element on the basis of mass of the sample after soaking time.

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

Validation

Specific methods used for validation of results depending on the technique

Quantification of the error

Quantitative or qualitative evaluation

Detection accuracy

Accuracy of the absorption level determination is affected by the preparation stage and the accuracy of balance used.

Advantages

- simple to perform

- no specific qualifications needed for the operator.

- can be performed on-site and in laboratory

Disadvantages

- does not account for any type of reactive process that ties up water

- assumes that all the weight gain is due to water

- short duration of submersion compared to what might happen in long term conditions.

Possibility of automatizing the measurements

Water resistance test may be partially automatized in such a manner that samples will be placed and taken out by a programmed equipment and the time of immersion will be designed in automatic software, however full procedure has to be supervised, taking into account the process of collecting the samples and decisions making.

Barriers

The periods of time designed for the test depends on the porosity of the material under studies.

Existing standards

- BS 1881: Part 122: 1983 - Method for Determination of Water Absorption.

- ASTM C 642-90, Standard Test Method for Density, Absorption, and Voids in Hardened Concrete.

- PN-EN 772-11:2011 Masonry test methods - Part 11: Determination of water absorption of aggregate concrete, artificial stone and natural stone masonry caused by capillary rise and initial water absorption of ceramic masonry elements.

- PN-EN ISO 16535:2019-08 Thermal insulation products in construction - Determination of water absorption during long-term immersion.

- RILEM Test Method – Test No. 11.4. Measurement of water absorption under low pressure.

Applicability

Relevant knowledge fields

Industry:

- pulp and paper quality control,

- powder testing,

- thermal-insulating materials testing,

Geotechnics:

- soil absorption testing.

Performance Indicators

- spalling

- cracks.

Type of structure

- pavement slubs,

- curbs

- bricks

Spatial scales addressed (whole structure vs specific asset elements)

There are no specific asset elements for testing. However, method is useful in testing bricks, which absorbs water and release air.

Materials

- concrete

- polymer

- aggregate

- paper.

Available knowledge

Reference projects

Not reference projects.

Other

BOSMAL – water resistance tests