Weight In Motion systems (WIM)

Goal(s)

Main objective

The infrastructure of bridges can be damaged under loads of vehicles. For this reason Weight in Motion (WIM) systems are utilized for traffic data collection and prevention of the overload of the structures. The vehicles with load above the maximum tolerance contribute to the deterioration of the roads and bridges thus, there is a huge need to control the overload on the infrastructure with accurate scales. On the European Union level, there are no uniform regulations since the technology is quite new, especially for advanced WIM systems measuring during normal traffic flow and not used in every country.

However, there are many attempts on the standardization and analysis of the WIM systems technology, data analysis, legal issues in different countries as can be found in other projects such as the REMOVE project for enforcement or the WAVE project for improving the accuracy and performance of Weigh-in-Motion (WIM) technology

The perspectives of WIM systems technology are giving huge possibilities in global monitoring of the bridge structures with the understanding that uniform standards across the European Union need to be established.

Description

Functioning Mode

A WIM system implements the process of weighing a moving road vehicle by first measuring the dynamic (varying with time), a vertically-downward component of the tire force from each wheel on the vehicle as the vehicle passes on a smooth road surface over specially-designed sensors. Then, the characteristics of these measured tire forces—along with other measured or calculated parameters such as speed and longitudinal position of the vehicle in the traffic lane are used to estimate the gross-vehicle weight and the portion of that weight carried by each wheel, axle, and axle group of a corresponding static vehicle.

WIM systems consist of:

- WIM sensors embedded in the roadway surface or placed under/on the bridge deck for detection of the exceeded weight, classification of the vehicles. Typically used sensors are: bending plates, load cells, quartz piezo sensors, polymer piezo sensors, and strain gauge strip sensors.

- Electronics which are needed for the control of the system functions and to provide vehicles records,

- Infrastructure such as junction boxes, directional bore, cabinet, poles, conduit needed to connect parts of the system,

- Support devices, mainly power supply which can be A/C, solar or wind needed to run the system,

- Software and hardware to process, analyze, format, and report the data collected during the measurements,

- Communication devices including a cellular modem or telephone jacks.

WIM controller is placed on the roadside cabinet for convenient access to the interface.

Types

There are six main types of WIM systems depending on the application and technology:

- Static weighing - the static weighing of road vehicles has an important relationship to WIM. The static weighing results are, in most cases, used as the reference values when testing and calibrating a WIM system. Static weighing systems are in many countries around the world legally approved for direct enforcement or trade applications.

- High-Speed Weight-in-Motion systems – the weighing is carried out in the open traffic lanes at normal speed and under free-flow conditions. The measurements are affected by the vehicle dynamics that depend on a combination of the geometry of the road, the driving behavior of the driver, and the reaction of the vehicle suspension on the influences mentioned previously. More and less accurate systems are also available.

- Low-Speed Weight-in-Motion systems - the weighing takes place in a dedicated controlled area, mostly outside the main traffic lane, on a flat and smooth platform (generally made of concrete) that is longer than 30 m. In the weighing area, the velocity and transverse movement of the passing vehicles are controlled to eliminate the dynamic effects of the vehicle

- Bridge Weight-in-Motion systems - a dynamic weighing system where the sensors are attached to the soffit (bottom side of beams or deck) of a bridge, viaduct, or culvert. The sensors typically measure strains due to the bending of the bridge caused by the passing vehicles. In addition to the same vehicle information as provided by the pavement WIM systems, the B-WIM systems can also collect valuable data about structure behaviour that can be used for safety assessment of the bridge

- Dynamic On-Board WIM (OBW) systems are fitted to vehicles, rather than to the infrastructure. An OBW system will constantly measure the weight, axle, and wheel loads of the vehicle while it is moving. The measured weight data of the moving vehicle may be combined with location (GPS) data and stored. Used to manage heavy vehicle operation and to monitor compliance to access certain parts of the road network.

- Rail Weight-in-Motion systems – the dynamic weighing of rail vehicles to determine the weight of wagons to collect revenue from shipping companies and to ensure any shortfalls or leakage of goods upon arrival at the depot .

Process/event to be detected or monitored

The main purpose of the use of WIM monitoring systems for bridges is the detection of overloading of the structure and thus, any induced damages through service-life of the bridge.

Physical quantity to be measured (e.g. actions, displacements, deformations, dynamic structural properties, material properties including mechanical, electrical, and chemical properties, relative displacements of the two sides of a crack, etc.).

The most important physical quantities measured by WIM sensors are:

- weight of the vehicles (estimation)

- axle group loads, axle loads, wheel loads of the passing vehicles

- tire impact forces

- strain forces

- velocity of the vehicles

Process of measurement of dynamic tire forces of a moving vehicle on a road.

Induced damage to the structure during the measurement

No damage is induced during the measurement.

General characteristics

Measurement type (static or dynamic, local or global, short-term or continuous, etc.)

Measurement range

Measurement accuracy

- Gross vehicle weight - +/- 10%

- Velocity - +/- 5%

- Axle distances +/- 10 cm

- Vehicle length +/- 50 cm

Background (evolution through the years)

WIM systems were invented in 1950 by Clyde Lee. Historically were used mostly for the collection of the large samples of data for vehicle loads – for pavement design. Bending plates were among the first sensors used for weighing. New technologies of WIM sensors were developed such as wire, strip and bar sensors, capacitive, piezo-electric (ceramic, then polymer, and then quartz), and then - fiber optics. Bridge WIM was also introduced in the US in the late 70s and then developed in Europe in the 90s. In 1970 and 1980, data were used for bridge design and bridge assessment, mainly in fatigue, but also to estimate the extreme loads and load effects. WIM data were also used for traffic monitoring and statistics on road freight transport.

Performance

General points of attention and requirements

Design criteria and requirements for the design of the survey

Procedures for defining the layout of the survey

Sensibility of the measurements to environmental conditions

Preparation

Procedures for calibration, initialization, and post-installation verification

- First method is a static calibration used for sensors such as piezo quartz crystal bars and fibre optics sensors and is suitable for low-speed WIM systems with good quality pavement sites when weight measurements will be carried out. Calibration masses of various intensities are placed on the scale, in this case, sensor and the relation between them and the system measurement is established. For Bridge-WIM systems there should be used additionally a two or three axle rigid lorry, which has to be weighed – empty and full. If more lorries are used, the accuracy can be improved.

- Another procedure requires use of shock or pressure variation devices such as a Falling Weight Deflectometer or a Piezodyn. In this case calibration is not dependent on the pavement profile, speed, load or calibration vehicle characteristics. However the traffic lane has to be closed during the calibration which is a problem on highways or bridges with high traffic flow. On the other hand, this procedure can be used when WIM system is configured for measurement of the impact forces only.

- Third method require use of pre-weighed calibration lorries for measurement of the instantaneous axle impact forces. This is the most common, simple and direct calibration path for all kinds of WIM Systems. Consists of series of measurements along the WIM system with pre-weighed vehicles, performed for few days with repeatable environmental conditions – homogenous temperature and climate conditions. Traffic flow does not have to be stopped in this case.

- Another method requires use of instrumented calibration lorries for measurement of the instantaneous axle impact forces. Especially convenient for the multiple sensor arrays. The main issue of this type of calibration is the cost of the instrumented lorries and also the need to have skilled technicians on the site with specific knowledge on the operating mode. Method base on the fitting of WIM records to on-board measured impact forces for the same axis or wheel with at least three load cases, different speed levels, repeated subsequently .

- 4 runs at 75km/h (average target vehicle velocity)

- 2 runs at 60km/h

- 2 runs at 90 km/h

Procedures for estimating the component of measurement uncertainty resulting from calibration of the data acquisition system (calibration uncertainty)

Requirements for data acquisition depending on measured physical quantity (e.g. based on the variation rate)

Performance

Requirements and recommendations for maintenance during operation (in case of continuous maintenance)

Mainly there are three processes to be performed during the service-life of the WIM systems. The sensors and the pavement surrounding the sensors should be visually inspected, without interference in the traffic flow, to find any external damages and prevent further internal deterioration in specified intervals of time. Sensors maintenance depends on the type and configuration used, however any moving parts that can be covered with dust or other dirt should be also checked and cleaned. Calibration has to be repeated in specified periods of time and compared with the data obtained during first documented, initial calibration. Also in case of any discrepancies or suspicious responses registered at any given time to make adjustments to the system. Another important issue is the data quality control, mainly consisting of checks over stability of the system parts, electronics as well as reliability and reproducibility of the results.

Reporting

Recorded data are considered for further analysis. In reports there are marked any abnormal runs with a validation codes given by the system.

Standard report include:

- system manufacturer,

- period of test,

- date and time,

- test conditions,

- location,

- lane number,

- number of test vehicles,

- vehicle types,

- velocity [km/h],

- the gross weight, axle loads by axle rank or group of axle loads measured in motion,

- static references values of these weights and loads.

Lifespan of the technology (if applied for continuous monitoring)

No reliable information on the average performance of the bridge WIM Systems at the moment can be provided. WIM systems offer continuous monitoring for at least 7 years when properly maintained/calibrated.

Interpretation and validation of results

Expected output (Format, e.g. numbers in a .txt file)

Data are displayed on the interface of WIM System or in a form of report when exported. Thus expected output consist of:

- gross vehicle weight,

- axle group loads, axle loads, wheel loads of the passing vehicles,

- vehicle record (depending on the system configuration and application), consisting of:

- identification (registration) number, date and time

- location: road number, direction, traffic lane,

- number of axles and axle distances,

- total vehicle length and/or wheel base,

- vehicle classification,

- vehicle speed.

For some configurations of the system also additional data can be exported:

- single/double tyre detection

- lateral position of the vehicle

- tyre pressure distribution

- calibration coefficient of the WIM sensors

- error code (to validate or eliminate measurements)

If the system is connected with other sensors or devices output will also include:

- height/width of the vehicle

- overview picture of the vehicle

- picture of the licence plate or registration number

- picture of dangerous goods identification shield

- code of dangerous goods shield

- temperature of the pavement or bridge, at one or several locations;

- deflection of the pavement

Interpretation (e.g. each number of the file symbolizes the acceleration of a degree of freedom in the bridge)

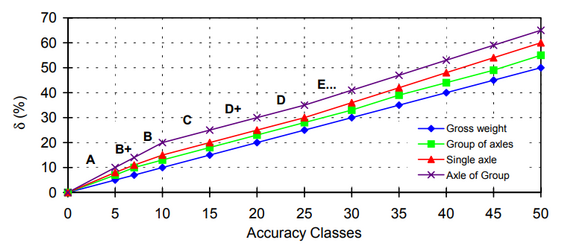

Test results are analysed with accordance to the COST323 specification. For gross vehicle weights there are defined probabilities of lying within a percentage range of static values. Estimated weights are then used to check which accuracy class has been achieved and whether it meets the weighting criteria for a given road. Data collected in short period of time, for instance in hours are used for real time traffic information and management, while data collected through weeks/years are used for maintenance of the roads or bridges, statistics and operation.

Validation

Specific methods used for validation of results depending on the technique

Quantification of the error

Quantitative or qualitative evaluation

Detection accuracy

The accuracy is referred to the static loads and weights mostly, for impact forces applied by the wheels/axles on the pavement and sensors. There are specified several accuracy classes, predefined for weight estimations by WIM systems. These classes are fully presented in the standard COST 323. Accuracy is affected by the calibration process in the initial phase and during service life and should not be assessed on the aggregated data. Specific tolerances are given for a load from:

- single axle,

- group of axles.

For bridge WIM systems accuracy tolerances specified for a group of axles in the COST 323 are not applicable. Accuracy classes mentioned in the European WIM Specification are derived by a statistical approach explained further in Appendix 1 paragraph 8.2 and applied for most of the WIM systems with specified confidence intervals.

Accuracy levels depend on the requirements, depending on the applicability, for instance for legal purposes 90-95% will be required, while for infrastructure on the level 80-90%. However, accuracy levels can be adjusted depending on the final user’s needs.

Advantages

- Automated non-stop traffic data collection

- Optimized infrastructure and maintenance planning

- Tracking of special transports

- Reliable calculation of remaining bridge lifetime:

- Reduced risk: early detection and continuous monitoring of critical structures

- Longer bridge lifetimes: overloaded vehicles are prevented from crossing the bridge

- Improved traffic safety

- Structural health monitoring: monitoring changes in a bridge’s structural behavior - faults are detected at an early stage

Disadvantages

- Lack of standardization

- Costs of the equipment,

- Costs of the maintenance of the system

- Legal issues

- Depending on the systems – problems generated with the closing of the traffic flow

Possibility of automatising the measurements

WIM Systems are a complex monitoring systems, which already work in an automatized manners. In Germany, in 2000-2002 there was finalized European Union project on the topic of: Technologies for Optimising the Precision of MS-WIM of Road Transports to Improve Overload Control and European Procedures for Enforcement, which aimed in improvement of the technologies for higher traffic safety . Future considerations of the development of WIM Systems mostly include use of new technologies and increase of the accuracy of existing systems,

Barriers

The main barrier in the application of WIM systems is the lack of standardization and uniformity in traffic management solutions across the European Union and the availability of the technology in different countries. Throughout the European Union, there is a high level of disparity in how the issue of overloading is dealt with, both in terms of the legal basis, enforcement, and technical and functional applications. Incidental use of WiM technology currently in the EU is another operational barrier as well as issues regarding acceptance by the Road Transport Industry in different countries.

Existing standards

- COST 323 Post-proceedings of the Second European Conference on weigh-in-motion of road vehicles, Lisbon, 14th to 16th September 1998.

- ASTM E1318-09 Standard Specification for Highway Weigh-In-Motion (WIM) Systems with User Requirements and Test Methods is a primary WIM standard.

- ASTM E867 - 06(2020) Standard Terminology Relating to Vehicle-Pavement Systems

- NMi International WIM Standard: Specification and Test Procedures for Weigh-in-Motion Systems, NMi Certin, Dordrecht, Netherlands, 2016.

- The OIML R-134 [OIML, 2004] from the International Organisation for Legal Metrology, the recommendation for ‘Automatic Instruments for weighing road vehicles in motion’ for use in enforcement for low-speed weighing.

Applicability

Relevant knowledge fields

WIM systems technology is used for specific applications:

- statistic in traffic loading – planning and design of future road networks,

- analysis of transport flows,

- collection of evidence for Government policy,

- achievement of compliance with loading regulations

- tolling by weight – fair toll prices

- industrial applications at ports and logistic centers,

- rail track and maintenance.

Performance Indicators

- overloading

Type of structure

- bridge

- railway

- road

Spatial scales addressed (whole structure vs specific asset elements)

WIM systems are designed for whole structure monitoring such as bridges, highways, motorways, or railways.

Materials

- concrete,

- steel.

Available knowledge

Reference projects

WAVE project:

- WAVE (2001a), Multiple sensor WIM, Report of Work Package 1.1, WAVE, ed. D. Cebon, University of Cambridge.

- WAVE (2001b), Bridge WIM, Report of Work Package 1.2, WAVE, ed. E.J. O'Brien, University College Dublin.

- WAVE (2001c), A Data Quality Assurance System for the European WIM Database, Report of Work Package 2, WAVE, ed. R. Henny, Rijkswaterstraat, Delft.

- WAVE (2001d), Durability of WIM system in cold climates, Report of Work Package 3.1, WAVE, ed. B. Hallström, SNRA, Borlange.

- WAVE (2001e), Calibration of WIM systems, Report of Work Package 3.2, WAVE, ed. M. Huhtala, VTT, Helsinki.

- WAVE (2001f), Fibre Optic WIM systems, Report of Work Package 4, WAVE, ed. J-M.Caussignac, LCPC, Paris.

REMOVE project:

- REMOVE: Final Report

- REMOVE: Application Terms utilized in Vehicle Weighing

- REMOVE: WP4 - Cost Benefit Analysis

- REMOVE: WP3 - Future Enforcement Strategy

- REMOVE: WP2 - Technical Issues

- REMOVE: WP1 - Legal Issues

BRIDGEMON PROJECT:

- WP1 – Improved Bridge-WIM algorithms

- WP2 - General Overview

- WP3 - Structural Health Monitoring of Railway Bridges

TOP TRIAL:

Milestones:

- Realisation, operation and evaluation of WIM trial

- Improvement of accuracy of truck load measurement

- Recommendation for European code of praxis for enforcement.

Major milestones will be:

- MS1: Trial concept and specification

- MS2: Pre algorithms, test site hand-over, press conference, web page

- MS3: Information exchange platform, workshop

- MS4: End of trial period, accuracy improvement and evaluation report, CBA report, draft code of practice for enforcement

- MS5: WIM enforcement workshop, video, project finalisation, final report

Other

Manufacturers websites:

International Society for Weight in Motion in Switzerland:

European Roads Police Network: